Categories

Recommended

Fully automatic MOCA melting system/Feilong Polyurethane machine manufacturer/Auxiliary equipment/Polyurethane curing agent melting equipment

Product Name: MOCA (Moca) Melting Device Application field: Specifically designed for the polyurethane (PU) industry, it is used to melt solid MOCA (3,3' -dichloro-4,4' -diaminodiphenylmethane, a common PU chain extender), ensuring precise feeding after liquid-state, and improving production efficiency and product quality.

Product Details

Core functions:

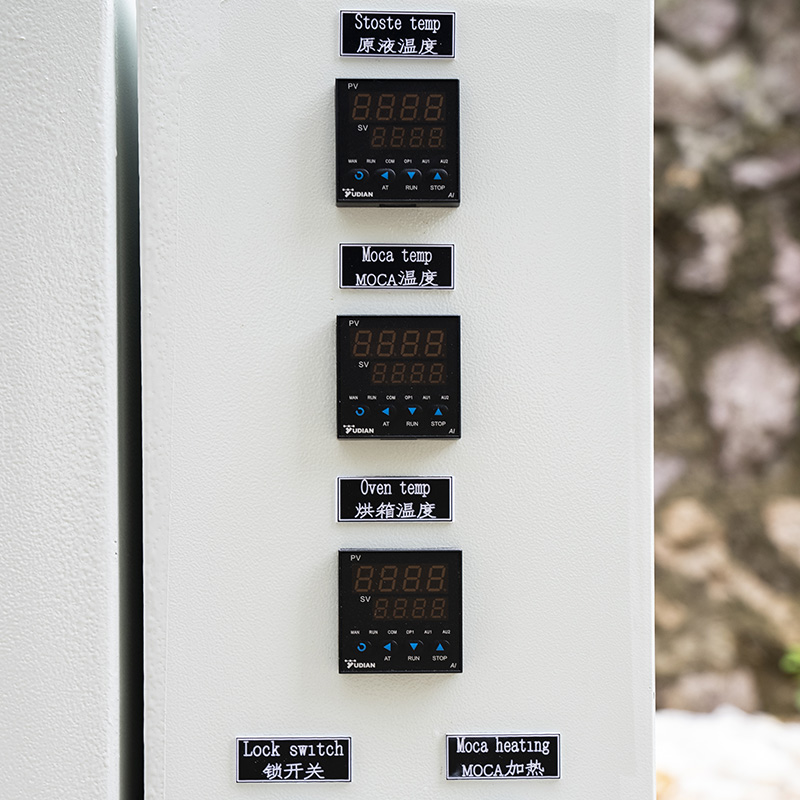

• Precise temperature control: Equipped with a PID intelligent temperature control system (adjustable from 50 to 150℃), with a temperature difference of ±1℃, it prevents MOCA from overheating and decomposing

• Uniform melting: Low-speed magnetic stirring/mechanical stirring is optional to ensure complete melting of the curing agent without residue

• Anti-oxidation design: An optional nitrogen protection interface is available to prevent MOCA from oxidizing and deteriorating at high temperatures

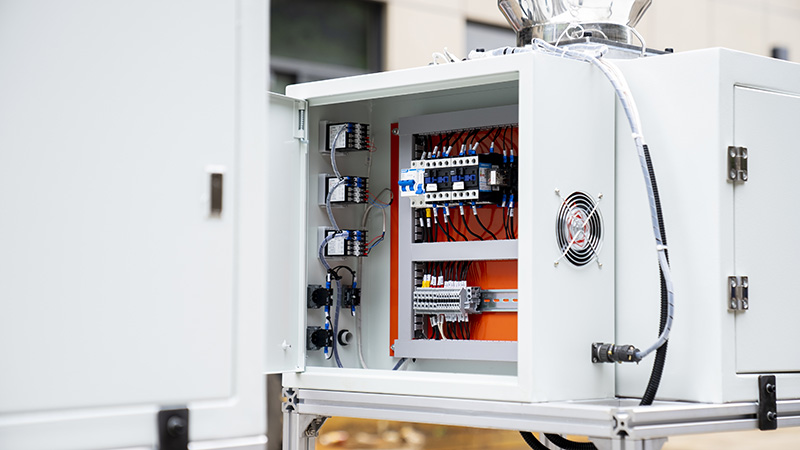

• Safety protection: Multiple overheat protection + anti-dry-burning device, in compliance with industrial explosion-proof standards (CE/ISO certification)

Application scenarios

▶ Polyurethane elastomer production (CPU/TPU)

▶ Manufacturing of rubber rollers, seals, and tire linings

▶ Small-scale trial production in the laboratory

Technical parameters:

Capacity: 5L/20L/50L/ Customized

Heating power: 3KW-15KW (depending on model)

Material: 304 stainless steel inner tank + ceramic heating module

Optional functions: Vacuum degassing, data recording, remote monitoring

Solution

✓ Solve the problem of low efficiency of traditional water bath heating - direct electric heating + heat transfer oil circulation, reducing energy consumption by 40%

✓ Avoid uneven manual stirring - Automatic stirring + wall scraping design increases melting efficiency by 60%

✓ Extend the service life of MOCA - Closed melting reduces water absorption and ensures curing effect

After-sales service

☑ 12-month warranty ☑ Free technical guidance ☑ 48-hour after-sales response