Categories

Recommended

Propellant polyurethane coating and mixing pouring machine #PUinjectionmoldingmachine #PUCastingMachine #PUpouringmachine #PUextruder

Customized for the coating of rocket/missile propellants | Supports customized formulation + size + temperature control modularization | Compliant with GJB safety standards

Product Details

Product Description

✅ Military-grade precision manufacturing

Used exclusively for the production of polyurethane coating layers for rocket propellants, solid fuels, and other high-risk scenarios. The equipment has passed explosion-proof certification (Ex d IIB T4), and the sealed structure eliminates the risk of solvent leakage.

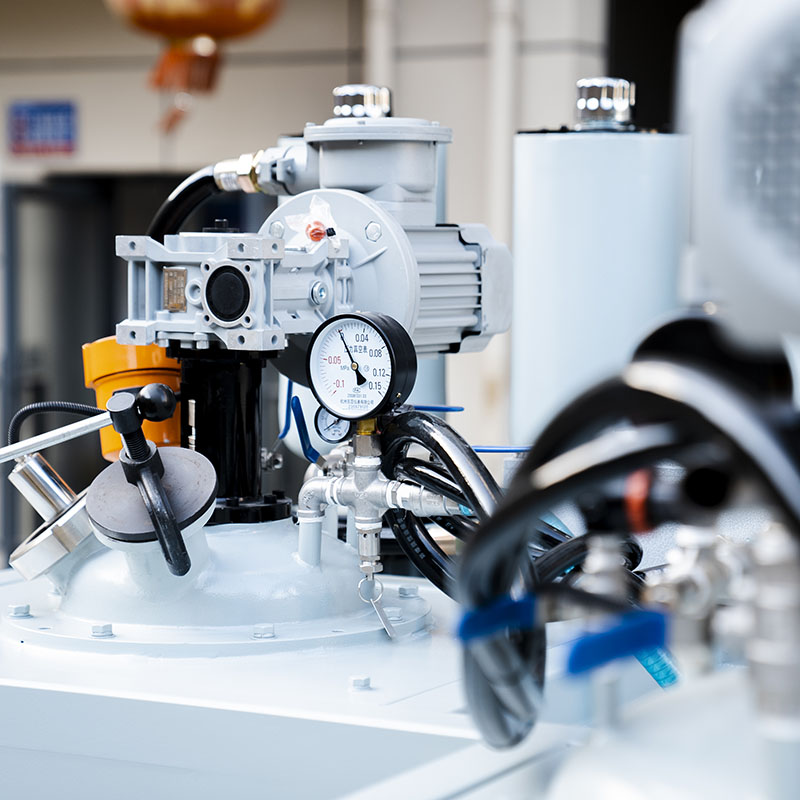

✅ Oil-heated precise temperature control system

It uses high-temperature conductive oil for circulation heating (temperature control range: ±0.5℃), eliminating the risk of local overheating and ensuring that the polyurethane mixture maintains a stable viscosity during the pouring process. The coating layer has no bubbles or stratification.

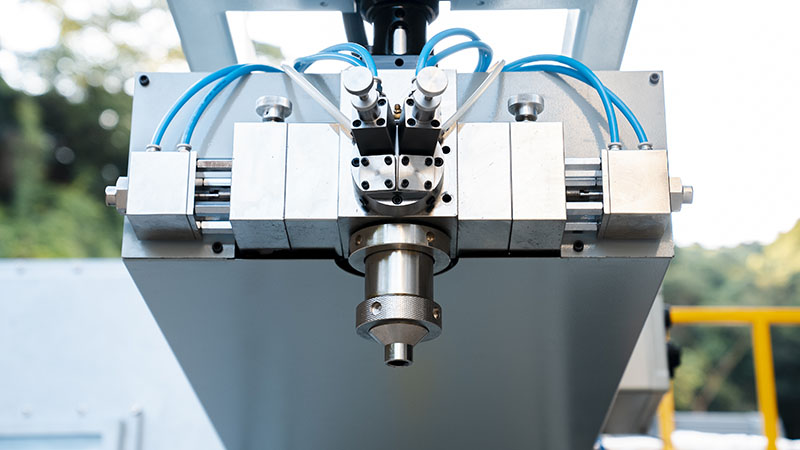

✅ Customized Hybrid Pouring Module

Supports customer customization:

▶ Adjustable mixing ratio of two components (from 1:1 to 1:10)

▶ Motion trajectory of the pouring head (XYZ three-axis linkage / integrated with mechanical arm)

▶ Vacuum degassing system (-0.098MPa)

▶ Moduleized material tank capacity (10L - 500L selectable)

✅ Intelligent Control System

PLC + touch screen human-machine interface, preset propellant coating process database, real-time monitoring of pressure/temperature/flow parameters, automatic shutdown and alarm in case of abnormal conditions, production data traceable.

Technical Specifications

Project Parameter Description

Thermal Control Method Thermal oil circulation, range 40℃ - 120℃

Mixing Precision Measurement error ≤ ±0.3%

Pouring Speed 0.1 - 50g/s, adjustable continuously

Protection Grade IP65 (operating area) / Explosion-proof certification for the entire machine

Customization Support Sizes, power, interfaces adapted to the production line

END PRODUCTS