Categories

Recommended

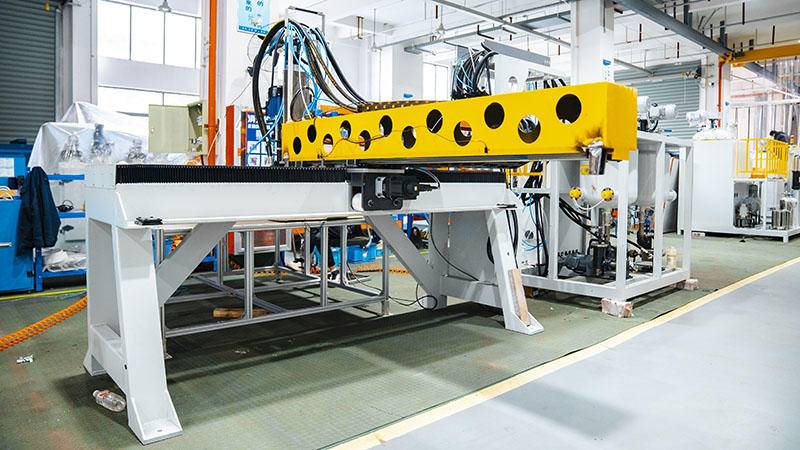

Automated pouring low pressure foaming machine | Continuous mixing foaming machine Customized PU hard foam / soft foam / special foam, etc.

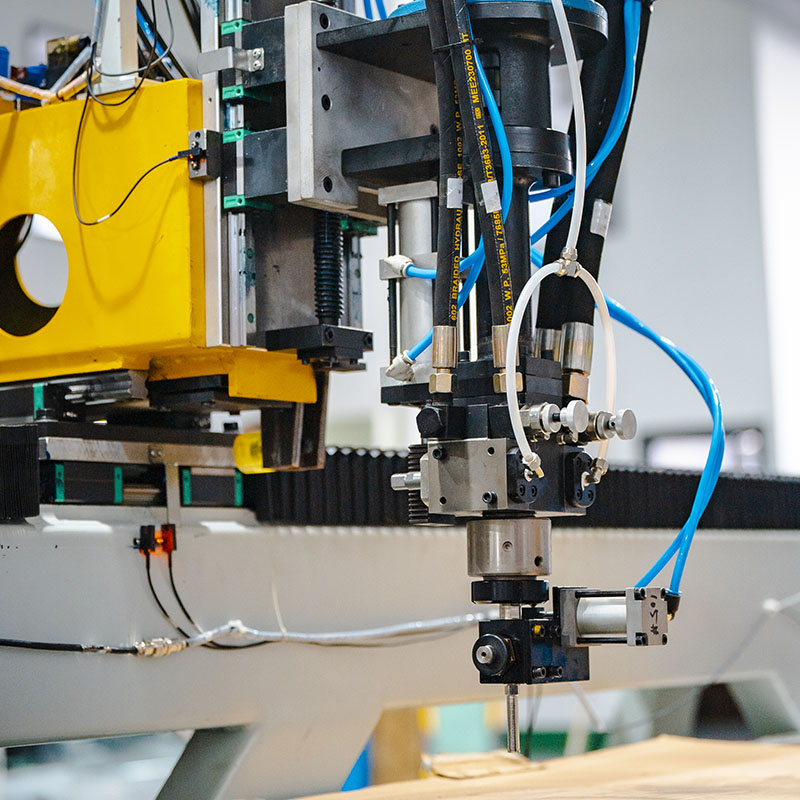

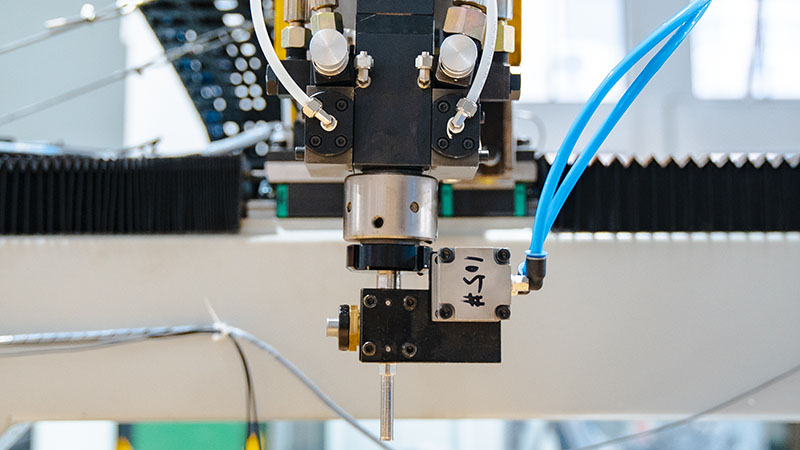

Core selling points: ✅ Intelligent automatic control: PLC + touch screen human-machine interaction, preset process parameters, one-click start of pouring, reducing manual intervention ✅ Low pressure high precision filling: 0.5 - 3 bar low-pressure injection, avoiding bubble formation, finished product porosity < 1% ✅ Two-component dynamic mixing: self-cleaning mixing head, measurement error ≤ ±1%, specially designed for RIM process ✅ Temperature control system: constant temperature management for two-component raw materials (temperature control accuracy ±1℃), suitable for PU/EP and other materials ✅ High efficiency and energy saving: closed-loop pressure control, energy consumption reduced by 30%, daily production capacity up to 200 - 500 mold cycles

Product Details

Technical Specifications

Injection volume: 50 - 2000g/s (customizable)

Work pressure: 0.3 - 3 MPa

Mixing ratio: 1:1 to 1:10 (AB materials can be adjusted freely)

Applicable materials: Polyurethane (PU), epoxy resin (EP), silicone, etc.

Overall machine power: 5kW - 15kW (depending on the model)

Protection level: IP54 (dustproof and splashproof)

Application scenarios:

▸ Automotive industry: seat foam, interior components, sound insulation pads

▸ Household appliance industry: refrigerator insulation layer, washing machine balance ring

▸ Construction materials industry: imitation wood furniture, decorative lines

▸ Packaging industry: precision instrument cushioning packaging

Service Support

⚙️ Free provision of process debugging training

⚙️ Support for OEM/ODM customized solutions

⚙️ Global logistics delivery

Note: Optional according to customer requirements - robotic arm linkage system / MES data connection / explosion-proof configuration

END PRODUCTS