Categories

Recommended

MDI Multi component PU Heating Injection Molding Machine | Polyurethane casting machine - rigid foam production line | CNC pouring machine

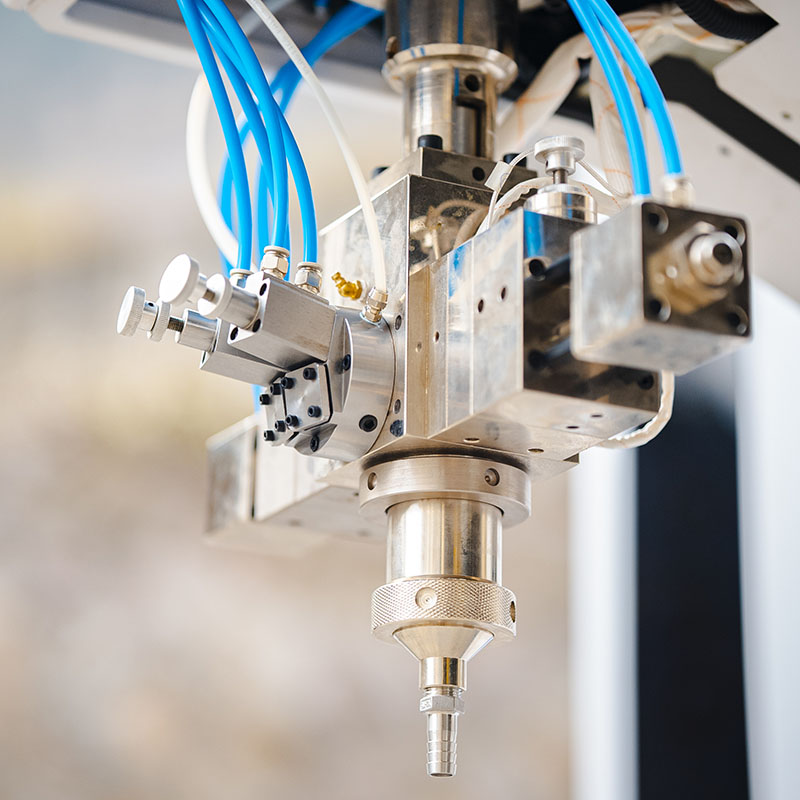

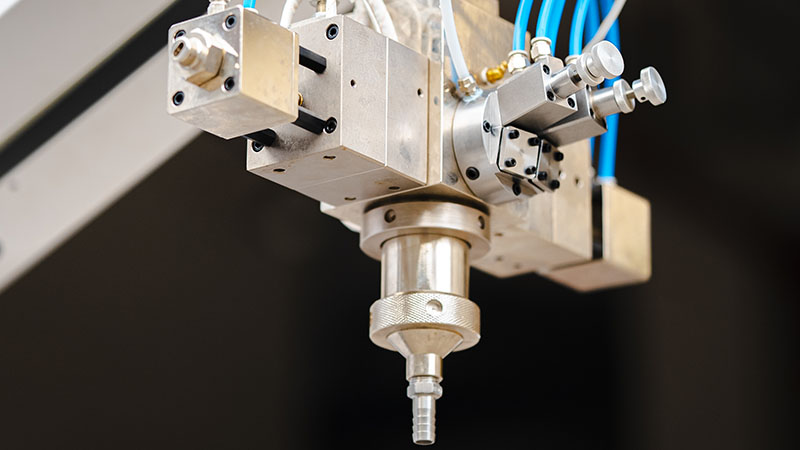

The MDI multi-component PU heating injection molding machine is a high-precision injection molding equipment specifically designed for processing polyurethane (PU) materials. It adopts the MDI (diisocyanate of diphenylmethane) system and is suitable for manufacturing high-quality and complex-structured polyurethane products. This equipment integrates advanced temperature control systems, precise metering devices, and multi-functional injection units, which can meet the production needs of high-performance PU products in industries such as automobiles, electronics, medical, and footwear materials.

Product Details

Core technical features

1. Multi-component precise metering system

Utilizing servo motor-driven precise metering pumps, the metering accuracy can reach ±0.5%

A/B dual-component (or multi-component) independent temperature-controlled conveying system

Dynamic mixing head technology, with a mixing uniformity of over 98%

Optional third component injection function (such as color paste, additives) can be equipped.

2. Efficient heating temperature control system

Segmented heating control, temperature control accuracy ±1℃

The heating power of the barrel can be adjusted, and the maximum heating temperature can reach 120℃.

Hot oil circulation mold temperature control system, mold temperature control range: 30 - 90℃

Intelligent PID temperature control algorithm, with fast response speed and small temperature fluctuations.

3. Advanced Injection Molding Unit

Clamping force range: 100 - 3000 tons (customizable as per requirements)

The injection pressure can reach up to 2500 bar.

Multiple injection speed control, meeting the requirements for forming complex products

Optional multi-station systems including rotating tables and sliding boards can be equipped.

Equipment parameters

| Project | Parameter range |

| Injection volume | 200-5000g |

| Injection rate | 200-500cm³/s |

| Locking force | 100-3000T |

| Template size | 600×600mm至2000×2000mm |

| Ejection stroke | 300-1500mm |

| Heating power | 15-60kW |

| Overall machine power | 30-150kW |

| Dimensions (of the shape) | Customized according to the model |

After-sales service

Provide equipment installation and commissioning services

Technical training for operators

One-year warranty, lifetime technical support

24-hour response service mechanism

Regular equipment maintenance reminder service

Optional functions

Automated pick-up robot arm

Online Quality Inspection System

Production data traceability system

Remote monitoring and diagnosis function

Customized mold solution

This MDI multi-component PU heating injection molding machine adopts the latest design concept and manufacturing technology. It can provide customers with efficient and precise production solutions for PU products, meeting the demands of various industries for high-quality polyurethane products.

END PRODUCTS