Categories

Recommended

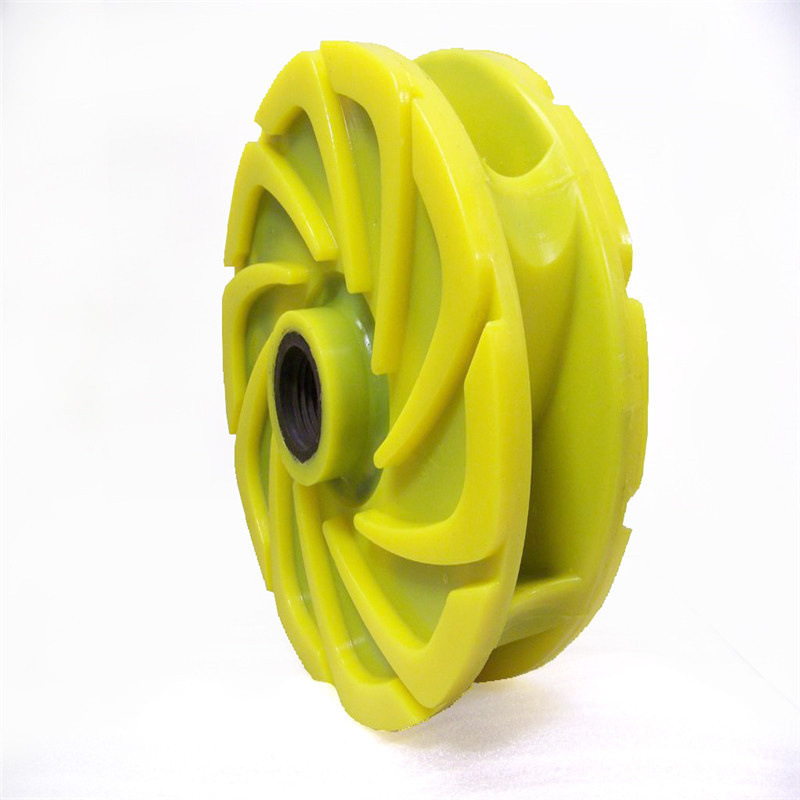

Soft roller elastomer casting machine | Special for polyurethane/silicone rubber rollers | Printing/textile/packaging roller production lin

Precision printing rubber roller Textile printing and dyeing rollers Packaging laminating roller Coating metering roller

Product Details

Military-grade gating system

Precision metering pump (proportional error ≤±0.5%)

Multi-axis synchronous centrifugal casting (rotational speed 100-2000rpm)

Zero-defect bonding technology

Plasma pretreatment of roller core (adhesive force ≥8MPa)

Real-time monitoring of curing by infrared thermal imaging

Intelligent hardness control

Online hardness testing (Shore 10A-90A, deviation ≤1A)

Gradient hardness formula storage (supporting 20 sets of formulas)

Super-precision dynamic balance

Schenk Dynamic Balancing System (Residual quantity ≤0.5g)

The final runout is ≤0.01mm (industry standard 0.03mm)

Digital Twin system

3D simulate the pouring process

Blockchain evidence storage of process parameters

Energy conservation and environmental protection design

Closed-loop circulation cleaning (solvent consumption reduced by 90%)

The energy consumption is 40% lower than that of traditional equipment

Technical parameters

Youdaoplaceholder0 Applicable roller diameter: Φ50-Φ600mm

Youdaoplaceholder0 Pouring length: 300-5000mm

Youdaoplaceholder0 Surface roughness: Ra0.2-3.2μm optional

Youdaoplaceholder0 Daily production capacity: 20-100 units (subject to specifications)