Categories

Recommended

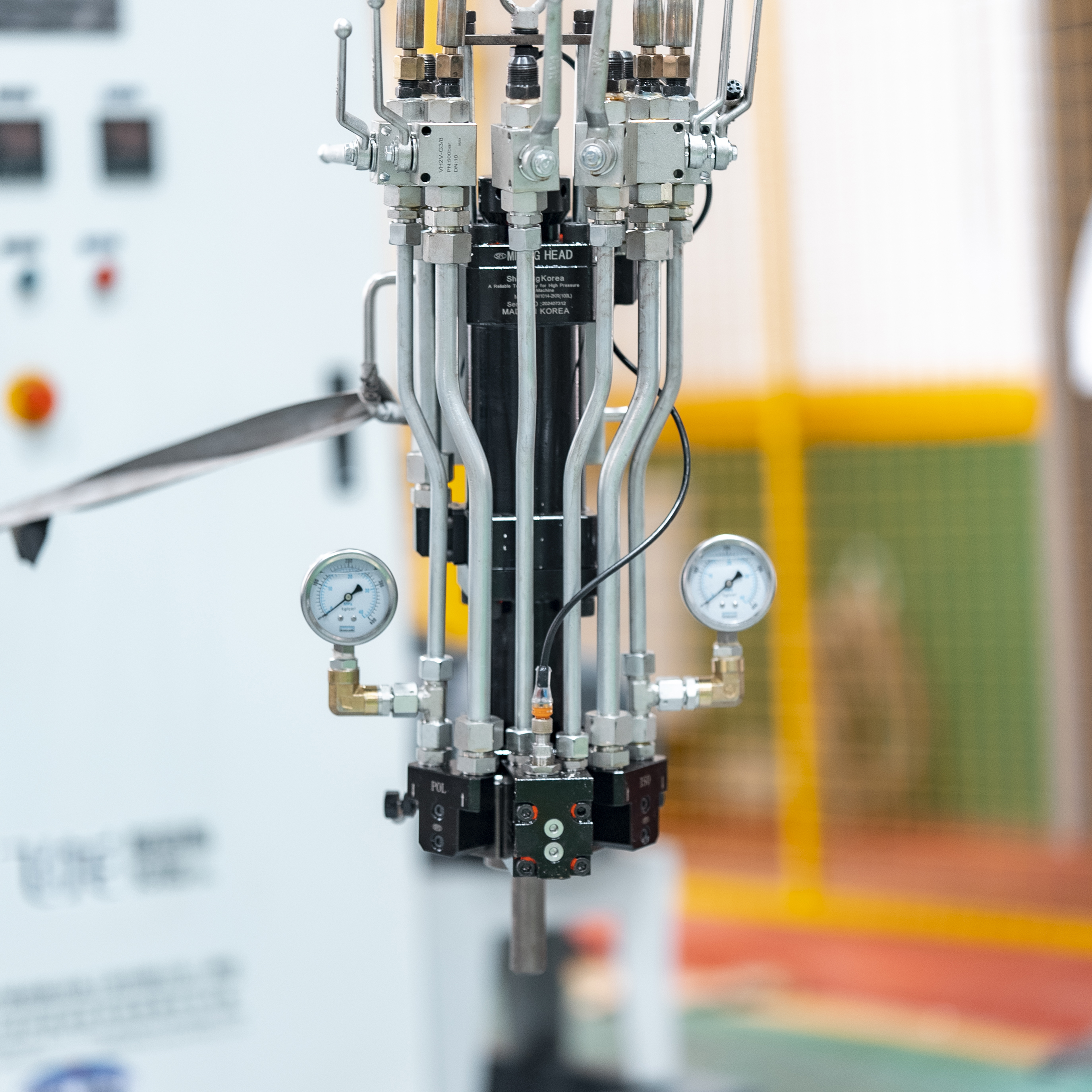

High pressure polyurethane foaming machine - soft foam seat production line | Impact mixing PU equipment - Customized multi component PU solution

Specialized in manufacturing high-pressure multi-component polyurethane foaming equipment, we provide a complete solution for the production line of soft foam seats. Our impact-mixing type PU foaming machine adopts the latest technology, with precise temperature and pressure control, enabling uniform formation of high-density foam. It is suitable for the production of automotive seats, furniture padding, medical shock-absorbing foam, etc.

Product Details

FEATURES

1.The system ensures precise metering with high-accuracy measurement devices, guaranteeing metering precision within 1%. The magnetically coupled metering pumps provide absolute leak-proof performance.

2.Featuring an L-shaped high-pressure self-cleaning mixing head with adjustable nozzle diameter, the mixing system achieves uniform atomized mixing under high pressure conditions.

3.The high/low pressure cycling switching mechanism alternates seamlessly between operational and standby modes, significantly extending the equipment's service life.

4.Temperature control is maintained by an integrated heating/cooling unit that provides constant temperature regulation with minimal deviation within ±2℃.

5.The electrical control system incorporates a 10-inch touchscreen interface and PLC module for automated management of temperature, pressure and injection flow parameters, with capacity to store up to 99 different production formulas for highly automated operation.

END PRODUCTS