Product Categories

Recommended

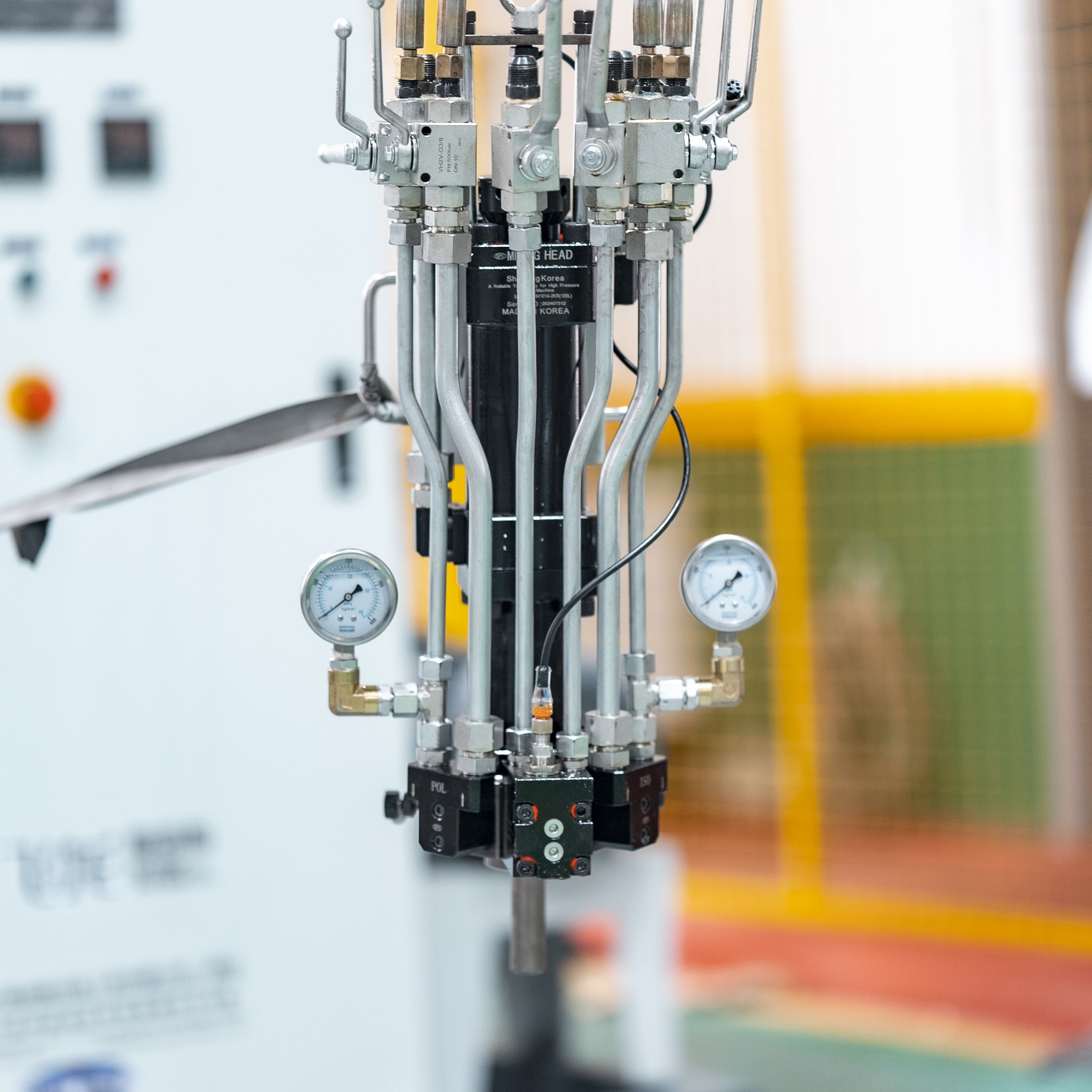

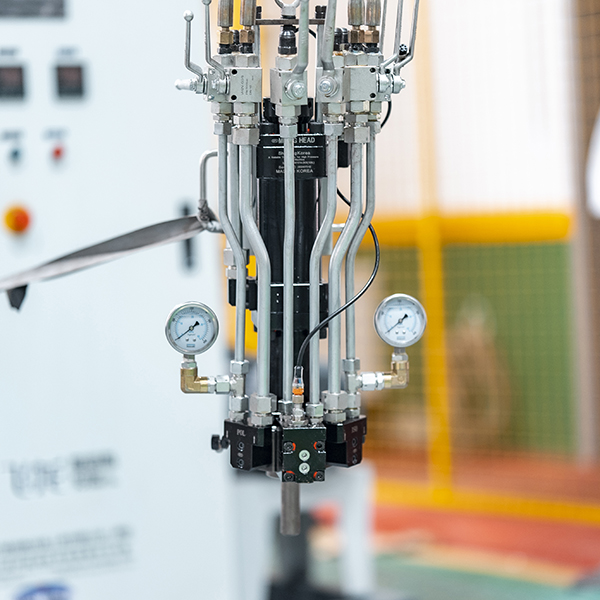

Polyurethane high-pressure foaming machine, dual nozzle synchronous injection of rigid/semi-rigid/soft foam production equipment for refrigerators, automobiles and furniture

Rigid foam: Insulation layer for refrigerators and freezers, building panels, and insulation for solar water heaters Semi-rigid foam: car instrument panels, steering wheels, armrests Soft foam: mattresses, sofa cushions, shock-absorbing materials for packaging

Product Details

Core advantages of the product

Dual-nozzle high-efficiency injection: The dual hybrid nozzles are independently controlled and can work simultaneously or alternately, increasing production efficiency by 50%. It is suitable for large-scale orders.

High-pressure precision foaming: Working pressure 100-200bar, uniform mixing without bubbles, fine cell structure, suitable for high-density rigid foam (refrigerator insulation) or low-density soft foam (sofa cushion).

Intelligent proportion adjustment: The ratio of A/B material (isocyanate + polyol) is adjustable from 1:1 to 1:5, with a flow error of ≤±0.5%, ensuring the stability of the product's physical properties.

Fully automatic control: PLC+ touch screen operation, integrating formula storage, automatic cleaning and fault alarm, reducing manual intervention.

Technical parameters

Working pressure: 100-200bar (high-pressure mixing)

Number of gun tips: Double independent gun tips (customizable for three guns)

Flow range: 10-100kg/min (adjustable)

Temperature control accuracy: ±1℃ (Electric heating/oil heating is optional)