Categories

Recommended

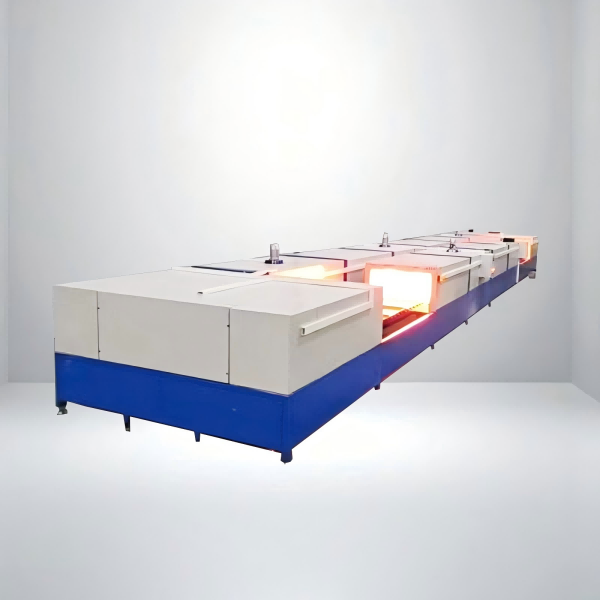

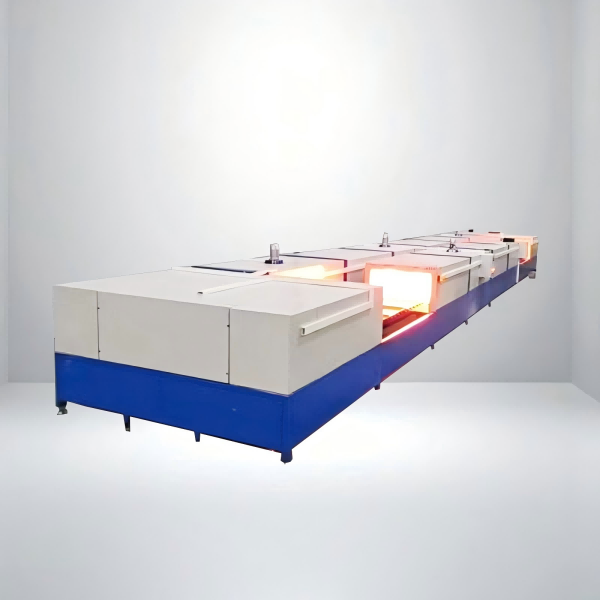

Fully automatic production line equipment for polyurethane elevator wheels | Mass production of elevator wheels | Supports ODM/OEM

Applicable scenarios: Batch manufacturing of elevator main wheels, guide wheels and compensating wheels, suitable for supporting production of brands such as ThyssenKrupp and Otis.

Product Details

Core

One-stop delivery: Covering the entire process equipment from raw material processing → precision casting → high-temperature vulcanization → dynamic balance detection → finished product packaging.

High precision and durability: Equipped with a German servo control system, the forming tolerance is ±0.02mm, and the wear resistance is more than three times the national standard.

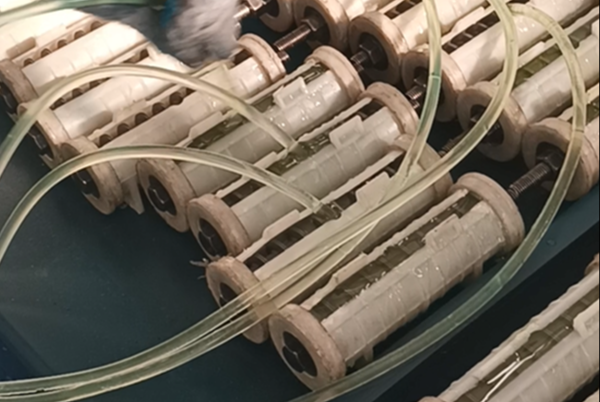

Intelligent and efficient: PLC automatic control, single-shift production capacity of 500 to 2,000 pieces, with a yield rate of ≥99%.

Customized services: Support the production requirements of elevator wheels of different specifications (Φ50mm-Φ300mm) and hardness (75A-95A).

Service Guarantee

24-hour technical guidance | Free trial operation and inspection | lifetime maintenance