Categories

Recommended

NDI polyurethane shock absorber dedicated production line | Micro-porous elastomer Products forming assembly line | Customization supported

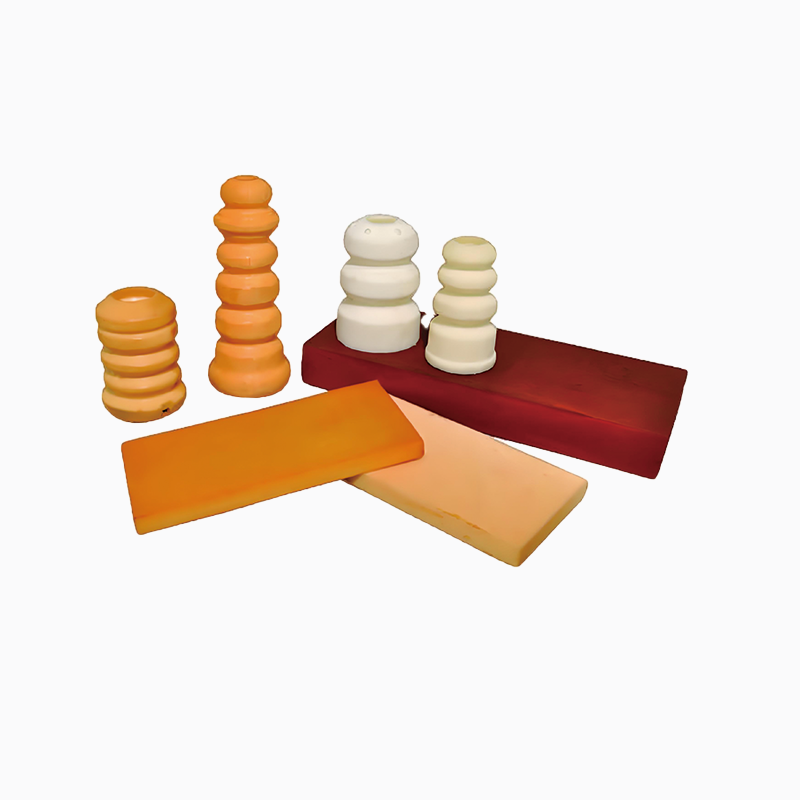

Application fields: New energy vehicle suspension shock absorbers | high-speed rail track gaskets | Industrial machinery buffer parts | high-end sports equipment elastic components

Product Details

Core

NDI polyurethane research technology - Optimizing the production of NDI system polyurethane shock absorbers to solve the problems of numerous bubbles and uneven density in the traditional MDI/TDI process

Full-process automation: raw material pretreatment → vacuum casting → curing and shaping → CNC cutting → finished product sorting. The entire process is unmanned, with a yield rate of ≥99.2%

Precision forming of micro-porous elastomers: Exclusive pressure-temperature closed-loop control system, adjustable pore size from 50 to 500μm, dynamic load performance improved by 30%

Modular design: Optional AI visual quality inspection/robotic arm stacking /ERP system integration, with flexible configuration of production capacity ranging from 200 to 1,500 pieces per day

Technical parameters

Youdaoplaceholder0 Pouring accuracy: ±0.5g

Youdaoplaceholder0 Curing temperature: 80-120℃±1℃

Youdaoplaceholder0 Production line cycle time: 90 seconds per piece (standard part)

Youdaoplaceholder0 Energy consumption: < 15kW/h