Categories

Recommended

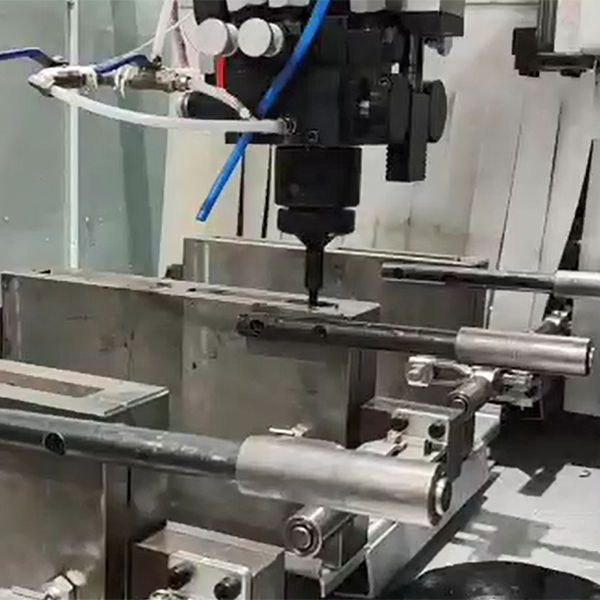

Polyurethane fully automatic railway gasket production line | Specialized for high-speed rail/metro/rail transit | Customized molds

Applicable customers: Railway engineering contractors | Rail transit component manufacturers | polyurethane product producers

Product Details

Core advantages

Fully automatic thermosetting molding - intelligent temperature control system, precise curing, ensuring high density and high strength of gaskets

Continuous and efficient production - automated assembly lines operate stably for 24 hours, increasing production capacity by more than 50%

Extralong service life - Polyurethane thermosetting material, resistant to compression deformation, oil and aging, with a service life three times that of ordinary rubber

Multi-specification adaptation - Supports gaskets of different sizes for high-speed rail, metro, ordinary rail, etc. (Molds can be customized)

Environmentally friendly and low energy consumption - closed-mold molding, no volatile pollution, and in compliance with the EN45545 railway fire protection standard

Technical parameters

Production capacity: 1,500-4,000 pieces per day (adjustable)

Forming temperature: 80-120℃ (precise temperature control)

Curing time: 3-8 minutes (adjustable)

Material compatibility: Polyurethane thermosetting elastomer (PU), flame-retardant grade raw materials