Chemfura Laboratory is a joint research institute established by Feilong and Hanke, serving as a key technical support platform for both companies. The laboratory provides comprehensive technical services in polymer materials, with a strong focus on polyurethane. By integrating equipment engineering expertise with materials science and application development, Chemfura Laboratory enhances innovation efficiency, ensures product reliability, and accelerates the transformation of research into practical industrial solutions for customers. The laboratory specializes in the customization of non-standard polyurethane samples, starting from a single unit. Supported by professional testing facilities and scalable production lines, it enables a seamless transition from prototyping to mass production, effectively meeting diverse requirements such as new product trials and pilot production.

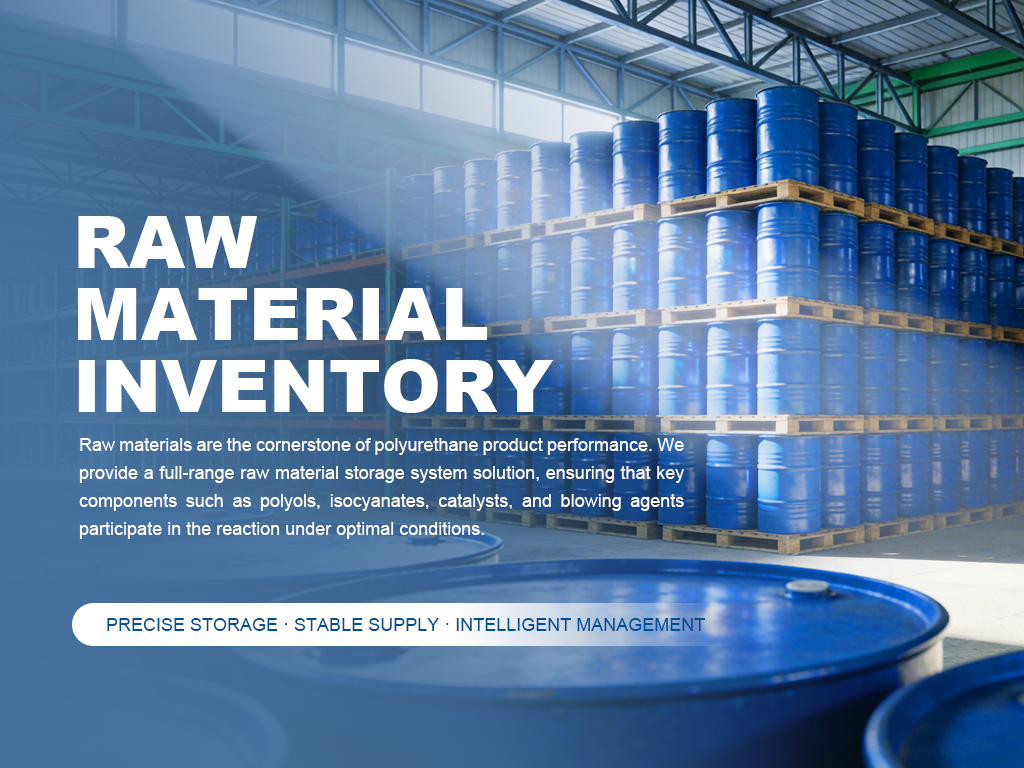

Raw material reserve management

Quick response mechanism

Small-batch production management

Product Inspection Management

Use Cases

Send your design

You will need to provide: · 3D CAD files (STEP/IGES format) · Application Requirements· Quantity and timing. We will review your design and recommend the best polyurethane solution for you.

Quotation and design

Instantly view prices and designs for manufacturability feedback. Once you have reached an agreement, place an order or fill out a purchase order.

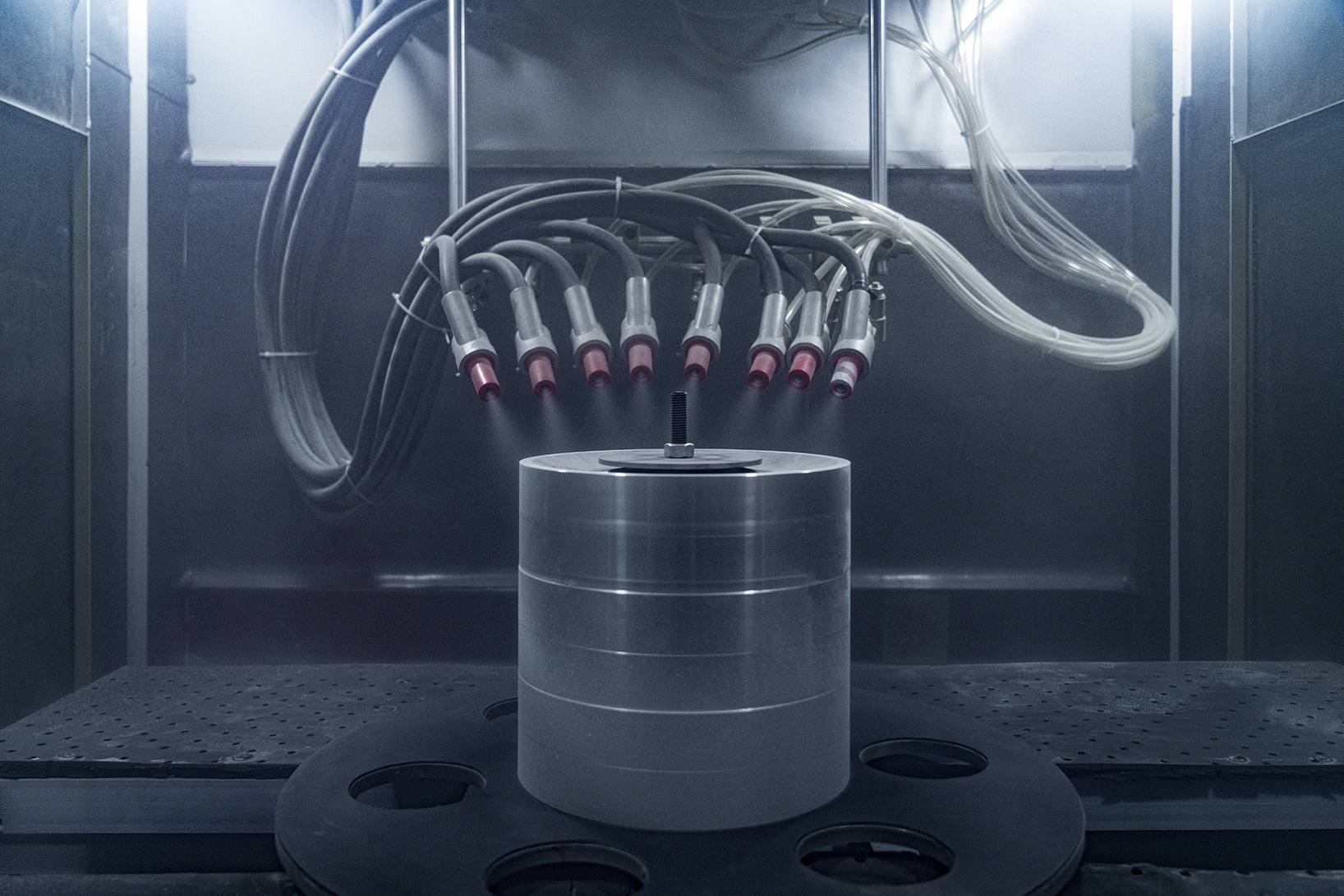

Design and make molds

We produce high-precision master parts that perfectly match your CAD data. This main component is used to make production molds.

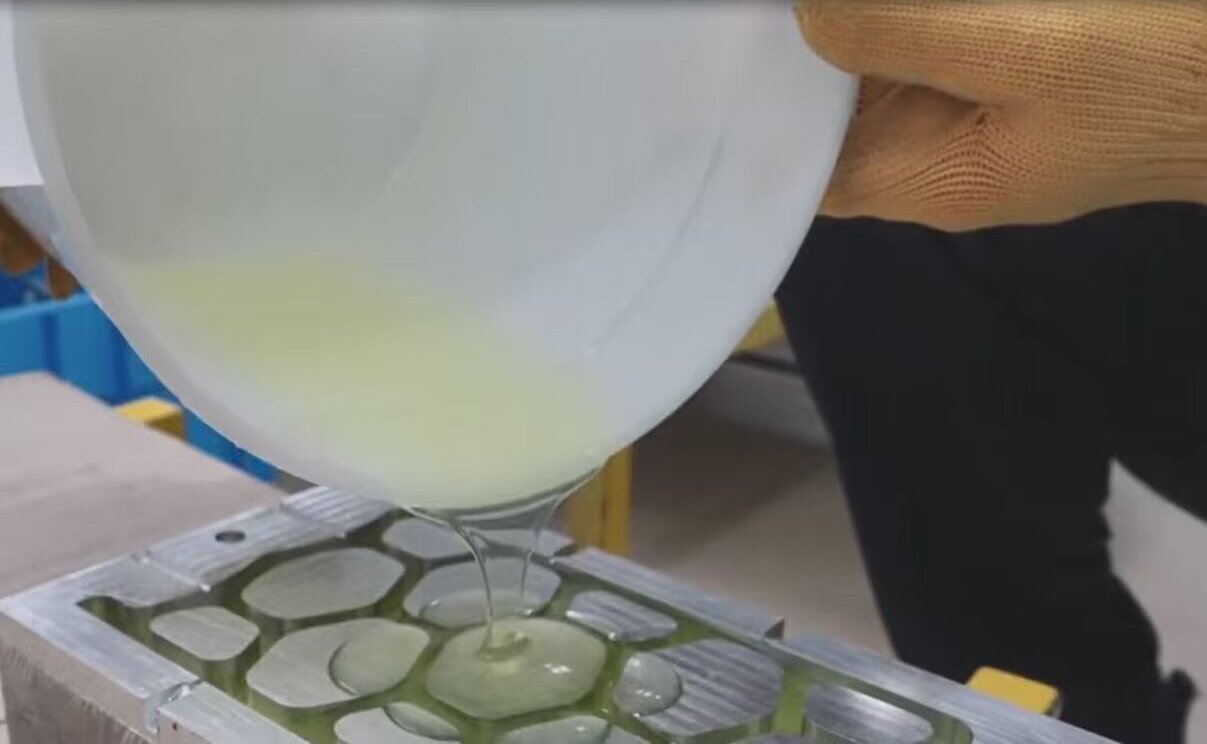

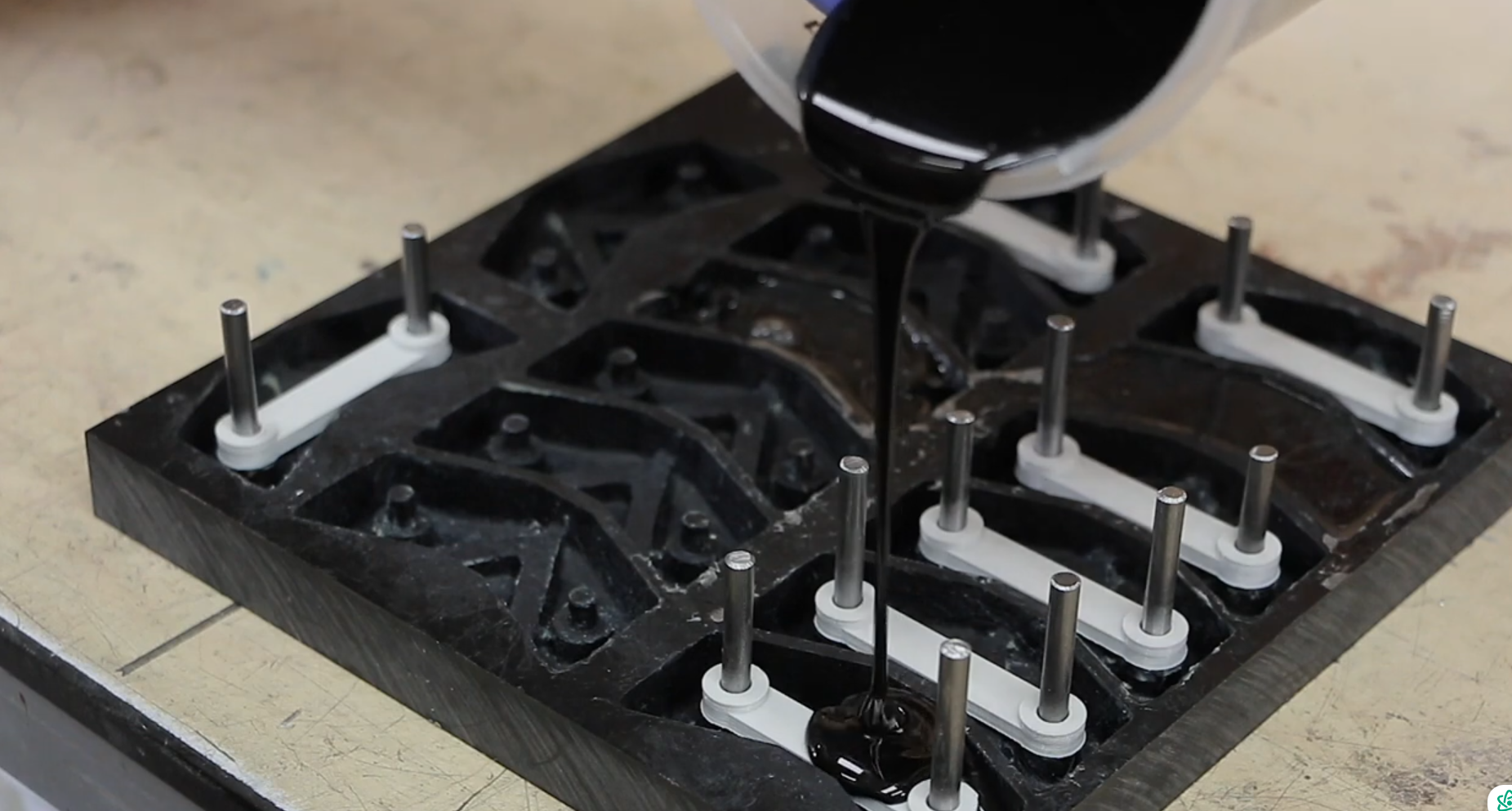

Sample Trial Production

Multi-material sample trial production with precise validation of product feasibility. Different materials are selected for iterative testing to identify the optimal solution, laying a solid foundation for stable and efficient mass production.

Small-Batch Scalable Production

From one trial order to mass production runs of up to 1,000 units, we provide full-process quality control at every stage. With efficient production management and rapid turnaround, fast delivery is ensured.

Product Testing

Qualification combined with rapid turnaround. Polyurethane samples undergo comprehensive testing, with authoritative test reports delivered within 3–7 days.

Completion Acceptance

Upon product completion, a standardized process is followed: re-inspection and qualification, data collation, and delivery confirmation.

Delivery and Testing

You will receive fully machined polyurethane prototypes ready for evaluation. Adaptability, dimensional, and functional testing can be conducted immediately.

Trusted raw material supplier

Directly sourced raw materials from the source, the quality can be traced throughout the process, and we will be a long-term reliable raw material supply partner with integrity and professional escort, so that cooperation can be worry-free.

Quality assurance

We passed AS 9100 | The ISO 9001 certified quality management system ensures reliable quality throughout the sample.

Quality control

All samples are dimensionally tested using calibrated equipment to ensure they meet your exact specifications.

FAQs

- Cast polyurethane elastomers

- Thermoplastic polyurethane elastomers

- Microporous polyurethane elastomers

- Raw material testing

- Formulation design and optimization

- Sample prototyping

- Small batch or pilot scale production

- Finished product testing and performance evaluation

- Physical and mechanical properties test

- Thermal and aging performance evaluation

- Chemical compatibility and stability analysis

- Machinability and application-specific testing

- Custom tests based on standards or customer requirements

- Material Testing: few days to weeks

- Prototyping and recipe optimization: weeks

- Small batch production and testing: varies by volume and requirements

- Application requirements

- Performance goals or standards

- Preferred materials or restrictions

- Expected yield

- Manufacturers and OEMs

- R&D teams

- Start-ups developing new polymers

- Companies validating materials before mass production