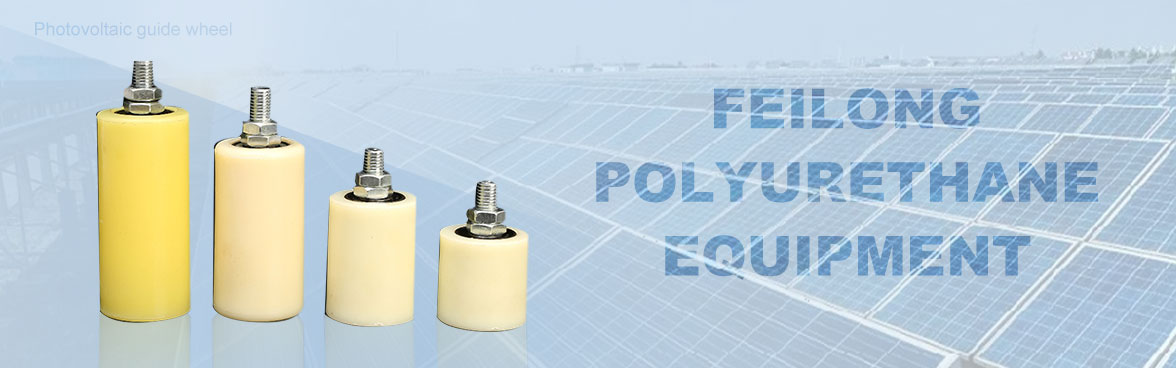

Field tests reveal that micro-bubbles (0.1mm scale) trapped during raw material mixing in conventional equipment are the primary cause of premature failure in diamond wire cutting guide wheels. These bubbles create localized hot spots during high-speed operation, causing catastrophic degradation in polyurethane elastic modulus—prompting Feilong Polyurethane Machinery to develop next-generation high-pressure equipment.

I. On-Site Findings: Three Critical Flaws in Guide Wheel Production

- Bubble-Induced Thermal Runaway- Cross-sections show 3–5 bubbles/cm³ (>200μm diameter) in conventionally cast wheels.- Consequence: Temperature at bubble zones surges to 128°C at 15m/s (validated by thermal imaging).

- Precision Collapse- Viscosity fluctuation: ±15% variation within a single material batch.- Direct impact: Groove width tolerance exceeds ±50μm, increasing silicon wafer wire-mark rate to 8.7%.

- Filler Agglomeration- SEM confirms: Undispersed nano-agglomerates accelerate local wear by 400%.

II. Feilong’s Technology Breakthrough: Two-Stage Vacuum Dynamic Mixing System

Core Innovation Workflow:

- Activate vacuum degassing (-0.095MPa)

- Adjust twin-screw mixer to 2,500 rpm

- Monitor real-time viscosity fluctuation <±2%

Three Process Revolutions:

- Zero-Bubble Solution- Industrial-grade vacuum chamber (leak rate <1×10⁻⁴ Pa·m³/s)- Result: Bubble size <50μm in cast parts (medical-grade PU standard).

- Micron-Level Precision Control- Servo motor-driven metering pump (0.001ml/pulse)- Client data: Groove width variation reduced from ±53μm to ±12μm.

- Nano-Filler Homogenization- High-shear dispersion disc (25m/s linear velocity)- Wear test: Only 7.3μm groove depth change after 100,000 rotations.

III. Client Transformation: Real Production Data

Before Upgrade:

- 2–3 guide wheels replaced per shift

- 3.2 hours daily downtime

After Feilong Equipment Deployment:

| Metric | Jun 2023 | Jun 2024 |

|---|---|---|

| Wheel Replacements | 27/month | 9/month |

| Cutting TTV* | 25μm | 8μm |

| *Source: Client MES report (Q2 2024), Total Thickness Variation |

IV. Engineering Insights

- 4.3ms Pressure Compensation- Aerospace-grade servo valve (validated via high-speed camera).

- Material-Adaptive System- 128 preset formulations; only 3 parameters adjusted for nano-filler changes.

- Predictive Maintenance- Triggers alarm at >0.8% metering deviation (false alarm rate <0.1%).

The technology of the Dragonfly Polyurethane equipment has extended the service life of the photovoltaic cutting guide wheels from 6 months to 22 months - this significant advancement stems from addressing the industry's pain points. Our innovations in eliminating bubbles, precise control, and wear resistance have set new standards. In the future, we will continue to strive to enhance the efficiency of photovoltaic manufacturing and provide solutions for all 17 failure modes recorded in the "Defect Spectrum of Photovoltaic Guide Wheels".