In industrial sectors like mining, construction, and chemical processing, advanced polyurethane machinery is essential for efficiently producing high-quality polyurethane screen panels. Feilong Polyurethane Machinery, a reputable manufacturer, has become a trusted global partner for PU screen panel producers, renowned for its precise process control and reliable performance.

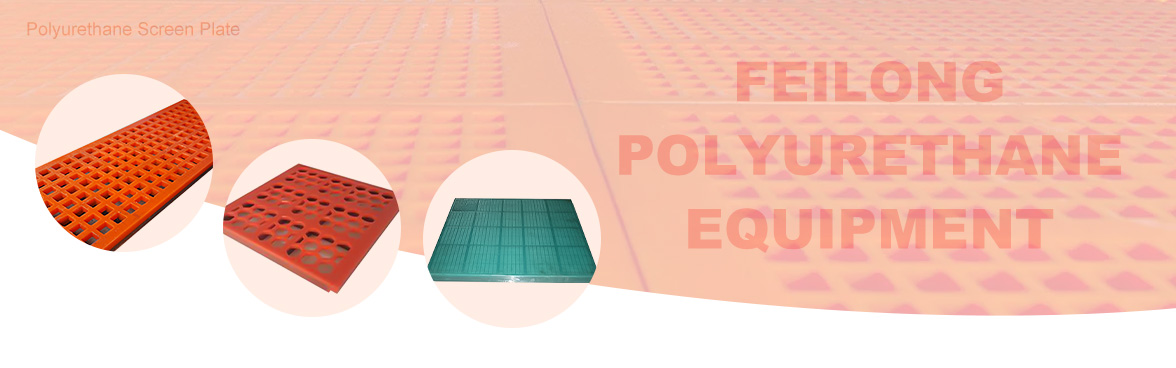

Core Advantages & Market Demand for Polyurethane Screen Panels

Polyurethane screen panels dominate industrial screening due to their proven advantages:

- Superior Wear Resistance: PU material lasts 3-5 times longer than standard steel, extending service life by 2-4x in coal mining applications.

- Higher Screening Efficiency: The elastomeric structure generates secondary vibrations, boosting material throughput by 15%-20%, especially effective for wet/sticky ores.

- Reduced Energy Consumption: Weighing only 1/3 of equivalent steel screens, they cut screening equipment power usage by 10%-15%.

Global mining reports indicate a $4.8 billion industrial screen panel market (2024), with PU screens growing at 7.2% annually. Rapid demand in Asia-Pacific necessitates efficient, stable polyurethane screen production equipment—a need met by Feilong’s solutions.

Critical Processes & Equipment Requirements for PU Screen Production

Producing premium polyurethane screen panels demands strict process control:

- Raw Material Processing:Moisture in oligomer polyols must be <0.05%. Feilong’s reactor achieves -0.095MPa vacuum and ±2°C accuracy at 120°C, cutting dehydration time by 40% and maintaining moisture <0.03%.

- Casting & Molding:Component mixing ratio (prepolymer A / chain extender B) requires ±1% precision. Feilong’s dispenser ensures 0.1% flow accuracy and molecular-level homogeneity via a 3,000r/min mixer within 3 seconds.

- Vulcanization & Curing:Temperature fluctuations must stay within ±1°C. Feilong’s zoned-heating platens limit variation to ±0.5°C, achieving 99.2% product qualification.

Feilong’s Technological Breakthroughs & Value

Key innovations tailored for PU screen panel production:

- Smart Process Control: Industrial IoT collects 128 real-time parameters; AI algorithms auto-adjust settings, limiting batch quality deviation to <2% (40% better than industry average).

- Energy-Efficient Drive: Variable-frequency hydraulics reduce idle energy use by 60%. Full-load consumption per unit is 12% below EU CE standards.

- Modular Design: Scalable output (500–2,000 panels/day), upgrades without downtime, and quick adaptation to market shifts.

Client Case: An iron ore project using Feilong machinery saw 35% higher PU screen output, defect rates drop from 3.8% to 0.7%, 22% lower production costs, and 14-month ROI.

Why Choose Feilong Polyurethane Machinery?

- Stable Quality: Consistent hardness (Shore A85±2), tensile strength (≥28MPa).

- Cost Control: 3%-5% less material waste via precision metering.

- Production Flexibility: Change molds in <30 minutes for rapid specification switching.

Feilong (ISO 9001 & CE certified) provides end-to-end services from process design to installation. Over 300 global polyurethane screen panel manufacturers rely on Feilong to boost production competitiveness.