As the tire industry undergoes a transformation toward low-carbon and high-performance solutions, polyurethane materials—with their high air tightness, aging resistance, and lightweight characteristics—are gradually replacing traditional butyl rubber as the core material for high-end tire inner liners. Yet this material innovation cannot be realized without the support of specialized manufacturing technology.

Feilong Polyurethane Equipment, a dedicated manufacturer of polyurethane processing machinery, provides precise, efficient, and intelligent solutions. By bridging the gap from material advantages to product value, Feilong helps tire manufacturers break through production bottlenecks and accelerate industrial upgrades.

Why Does Polyurethane Inner Liner Performance Depend on Specialized Equipment?

Tire inner liners significantly affect air retention, service life, and energy efficiency. Traditional butyl rubber liners have a gas permeability of 5–15 cm³/(m²·d·bar), requiring frequent refills. They are also heavy and limited in temperature resistance, making them unsuitable for the demands of new energy vehicles (NEVs) and high-end commercial tires that require low rolling resistance and long driving range.

Polyurethane brings remarkable improvements:

- Superior air tightness – Gas permeability of 0.5–3 cm³/(m²·d·bar), one-fifth to one-third that of butyl rubber, extending inflation cycles to 3–6 months.

- Lightweight advantage – Reduces tire weight by 30–50%, lowering vehicle energy consumption.

- Broad temperature stability – Maintains performance from –40°C to 120°C, suitable for engineering tires and aviation applications.

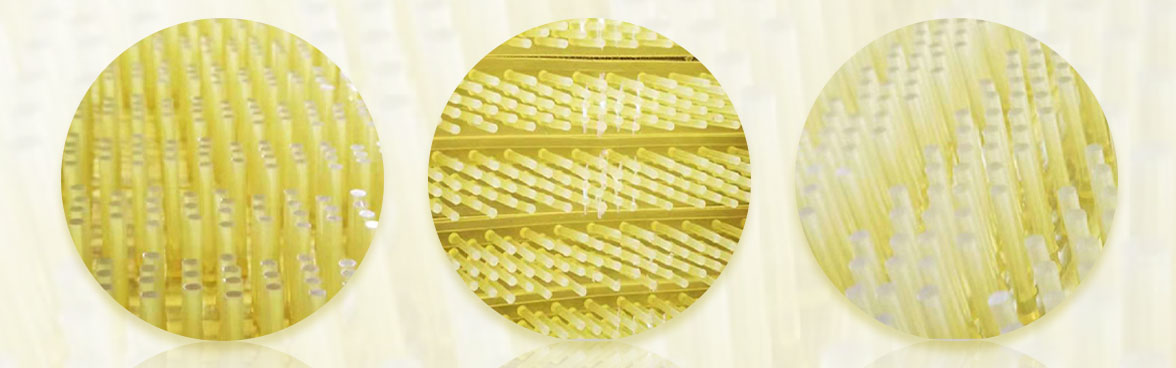

However, PU’s performance depends on precise manufacturing processes. From TPU (thermoplastic polyurethane) extrusion to PUR (thermosetting polyurethane) casting and curing, and from raw material metering to composite bonding, the equipment requirements are extremely demanding:

- Mixing ratios must be controlled within ±1%, or air tightness is compromised.

- Processing temperatures must stay at 180–220°C (TPU) or 60–80°C (PUR); a deviation of 10°C can reduce material performance.

- Bonding requires 0.02 mm thickness precision to prevent bubbles or delamination.

Feilong Polyurethane Equipment delivers the full-process precision needed to transform PU’s material strengths into product competitiveness.

Three Core Advantages of Feilong Polyurethane Equipment

1. Precision Control – Guaranteeing Stable High Air Tightness

PU inner liner air tightness is linked to molecular density, which depends on uniform mixing and forming accuracy. Feilong Polyurethane Equipment’s high-speed mixing machines with servo-controlled metering pumps ensure precise ratios of isocyanates and polyols. Its TPU extruders with multi-zone temperature control (±2°C) produce uniform thin films, reducing leakage points caused by uneven material distribution.

➡ A leading NEV tire manufacturer improved liner permeability after introducing Feilong Polyurethane Equipment—without altering raw materials.

2. High-Efficiency Production – Meeting Mass Production Needs

Passenger car tires often require million-level annual output, making equipment efficiency crucial. Feilong’s fully automated PUR casting lines integrate injection, curing, and forming into one streamlined process, ensuring stable production capacity. Its multi-station hot-press bonding machines accelerate adhesion while delivering strong peel resistance, lowering rework rates.

➡ In the commercial tire sector, manufacturers adopting Feilong Polyurethane Equipment’s solutions achieved shorter production cycles through equipment and process optimization.

3. Flexible Adaptability – Covering Multiple Polyurethane Types

Different tire applications demand different PU types:

- TPU – lightweight, ideal for NEVs.

- PUR – superior aging resistance for engineering vehicles.

- Modified PU – cost-effective for the mid-range tire market.

Feilong Polyurethane Equipment’s modular equipment design enables quick parameter switching—for example, adjusting extruder screw speed and temperature allows smooth transition from TPU film production to modified PU coating. Its casting systems support 10+ inner liner mold designs, meeting diverse needs such as run-flat tires and self-sealing tires.

➡ This flexibility allows tire makers to expand product lines without repeated investment, keeping pace with fast-changing markets.

From Equipment to Services – Supporting Tire Manufacturers

Feilong Polyurethane Equipment goes beyond equipment supply by offering comprehensive technical and service support:

- Process packages – Custom parameters for specialized PU types such as bio-based PU and flame-retardant PU.

- Smart maintenance systems – IoT-enabled monitoring of temperature, pressure, and other data for predictive maintenance.

- Green production solutions – Lower energy consumption compared with traditional equipment, plus support for TPU recycling, aligning with “dual-carbon” sustainability goals.

Conclusion

With the growing adoption of polyurethane inner liners in tire manufacturing, the right equipment is essential for companies seeking technological leadership. Leveraging decades of expertise, Feilong Polyurethane Equipment integrates precision control, efficient production, and flexible adaptability into its solutions, enabling tire makers to fully capitalize on PU materials.

Whether the demand is low rolling resistance for NEVs or aging resistance for engineering tires, Feilong Polyurethane Equipment provides customized solutions to drive product innovation and market competitiveness.