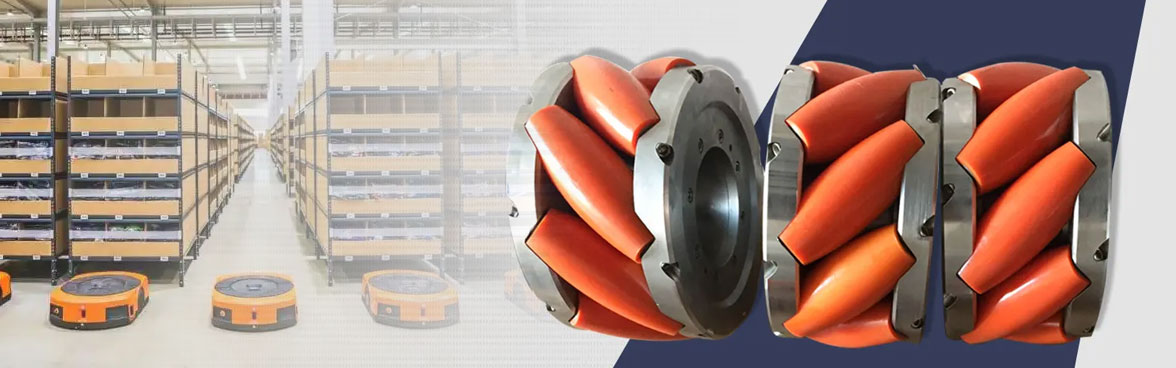

In today’s era of rapid automation and smart manufacturing, polyurethane Mecanum wheels—renowned for their omnidirectional mobility—have become the “core drivers” of AGV wheels, intelligent warehouses, medical robots, and specialized equipment. The production of these precision components relies heavily on high-precision wheel manufacturing and advanced polyurethane processing technology. With over 20 years of expertise, Feilong Polyurethane Equipment has become a leading provider of precision casting equipment for Mecanum wheels worldwide.

Precision Manufacturing: Millimeter-Level Accuracy at Industry-Leading Standards

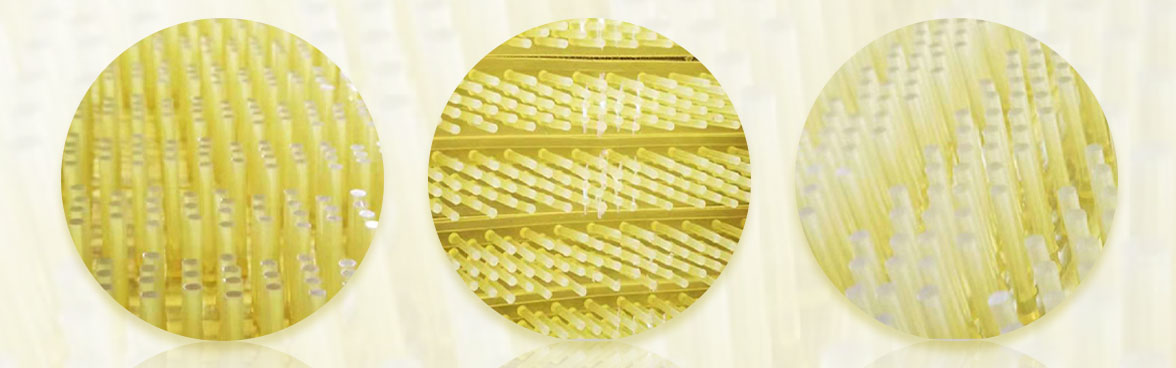

The competitiveness of Mecanum wheels lies in the precise angular arrangement of their rollers and the stability of polyurethane elastomer casting. Feilong Polyurethane Equipment’s equipment delivers military-grade metering accuracy (≤0.5% error) to ensure A/B components are mixed at the optimal ratio, preventing hardness inconsistencies and reduced wear resistance.

For the complex 45° roller structure of AGV wheels, Feilong Polyurethane Equipment’s modular equipment adapts to wheel sizes (50mm–300mm diameter) and roller counts (6–12). Its floating mechanical-seal casting head, equipped with multiple sensors and intelligent control, maintains ±1℃ stability during 8-hour runs, ensuring roller molding accuracy of ≤0.1mm—a 40% improvement over industry norms. This high-precision control provides the physical foundation for accurate omnidirectional movement in robot wheels.

Material Empowerment: From Formula to Performance Breakthroughs

Mecanum wheels demand extreme wear-resistant polyurethane performance: Shore hardness A60–95 for various flooring, 3–5 times higher wear resistance than rubber, and superior elasticity to reduce noise. In partnership with the Chinese Academy of Sciences, Feilong developed a formula-adaptive system powered by material performance prediction algorithms. This ensures polyurethane crosslinking density can be digitally customized.

- For logistics AGV wheels: Feilong Polyurethane Equipment produces polyurethane with wear loss ≤50mg/1000 cycles, extending service life by 50% compared to industry peers.

- For medical robot wheels: By controlling reaction temperature within ±2℃, rebound resilience reaches ≥60% while noise remains ≤60 dB—meeting surgical room standards.

This integration of equipment precision and material innovation makes Feilong Polyurethane Equipment the trusted partner for polyurethane Mecanum wheel manufacturing across multiple industries.

End-to-End Solutions: From R&D to Mass Production

Feilong Polyurethane Equipment provides full-cycle solutions for polyurethane Mecanum wheel production, from lab testing to large-scale manufacturing. In R&D, its lab casting machine with an 8-station parallel testing system can validate multiple polyurethane formulations (e.g., NDI systems) in 48 hours instead of 7 days.

For mass production, Feilong Polyurethane Equipment’s fully automated lines—equipped with industrial IoT—enable automatic mold handling, continuous polyurethane casting, and online quality monitoring. This achieves 500–1000 sets per day, with hardness deviation ≤3A and defect rates <0.5%.

For specialized needs such as military or polar exploration robot wheels, Feilong Polyurethane Equipment offers custom upgrades. Its synchronized low-temperature reactors and curing ovens produce wheels that remain elastic at –40℃. Independent tests confirm stable performance between –40℃ and 80℃, with degradation ≤5%.

Competitive Edge: Why Choose Feilong Polyurethane Equipment?

Compared with conventional machinery, Feilong Polyurethane Equipment’s polyurethane elastomer casting equipment offers three key advantages for Mecanum wheel manufacturing:

- Higher Precision – Roller accuracy ≤0.1mm, 40% better than industry average.

- Faster Efficiency – End-to-end production cycles shortened by 60%.

- Lower Costs – Material utilization +15%, energy savings +20%, downtime –30%, cutting costs by 25%.

More Than Equipment: A Long-Term Value Partner

Choosing Feilong Polyurethane Equipment means more than buying machines—it’s a long-term partnership. From AGV wheel process design to after-sales service, Feilong Polyurethane Equipment provides optimized solutions based on load capacity (100kg–500kg) and floor conditions (epoxy or concrete). Its technical team guarantees 24-hour service response and downtime under 4 hours—60% faster than industry standards.

As Mecanum wheels continue driving automation, Feilong Polyurethane Equipment ensures “mobility precision” through equipment precision, and empowers “industry innovation” through technological innovation. From intelligent warehouse wheels to medical robot wheels, Feilong Polyurethane Equipment provides the strongest foundation for truly flexible movement.