Precision Medium-Temperature Control System: The Core of MDI-Based CPU Elastomer Processing

In polyurethane elastomer production, temperature precision directly determines product stability. Feilong’s medium-temperature elastomer wheel production line features a dual-component independent temperature control system, ensuring A-component control at 60–100 °C and B-component control at 40–85 °C, with a deviation of less than ±2 °C. This accuracy fully meets the process requirements of MDI-based prepolymer CPU elastomers and provides a stable reaction environment for low-to-medium hardness materials (Shore A 20–85).

The equipment adopts a high-temperature-resistant, low-speed precision metering pump paired with a servo-driven system, achieving a mixing accuracy of ±0.5% — an industry-leading standard. In real-world testing at an automotive parts manufacturer, the equipment produced 500 batches of industrial caster wheels with hardness variation within ±1.5 Shore A, significantly outperforming the industry average of ±3 Shore A. This stability is driven by Feilong’s dynamic viscosity compensation algorithm, which automatically corrects flow rate within 0.3 seconds when B-material viscosity fluctuates by ±50 CPS due to temperature changes.

Patented Direct Pigment Injection: Redefining Color Consistency

Traditional polyurethane coloring requires pre-mixing pigments with raw materials, often leading to batch color deviation (ΔE > 3) and 15–20% material waste from equipment cleaning. Feilong’s patented direct pigment micro-control system fundamentally resolves these issues through three key innovations:

- Modular Mixing Unit: Integrates a pigment injection module at the mixing head, equipped with 316L stainless steel precision metering valves with a minimum injection rate of 0.1 g/s, supporting 1–5 colors simultaneously. After implementation by a medical equipment manufacturer, color consistency for surgical trolley casters improved from ΔE = 4.2 to ΔE < 1.8, achieving medical-grade color standards.

- Dynamic Dispersion Compensation Algorithm: The system continuously monitors pigment-to-material ratio, automatically adjusting the mixing head’s speed (4,000–6,000 rpm) and shear angle. In electronic conveyor roller applications, pigment dispersion uniformity improved 40%, and abrasion tests showed the wear resistance difference between colored and base regions reduced from 12% to below 3%.

- Optimized Cleaning Process: Adopts a dual air-liquid flushing system, reducing pigment residue to < 0.5 ml per cycle and cutting color-change cleaning time from 45 minutes to just 8 minutes.

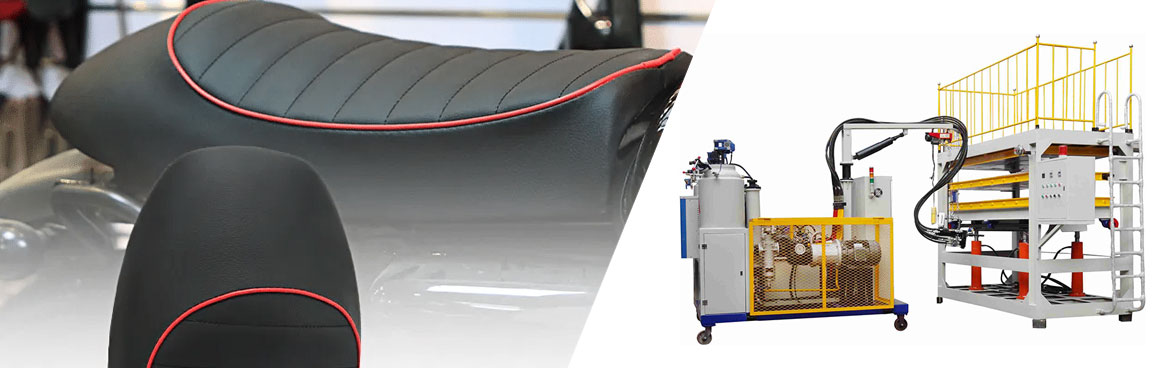

Customized Multi-Industry Solutions: From Heavy-Duty Industrial to Precision Medical Applications

Feilong’s medium-temperature wheel system delivers flexible customization across multiple industries:

- Industrial Applications: For heavy-duty forklift wheels (5–8 tons load), the gradient hardness forming process enables a continuous hardness transition from Shore D 80 at the wheel core to Shore A 90 at the surface by adjusting the A/B ratio (100:6–20).

- Medical Equipment: The ultra-low VOC process package for surgical bed casters integrates an optimized degassing system (vacuum ≤ 5 mbar) and controlled mold temperature curve, reducing VOC emissions to 0.1 mg/m³. The process has passed ISO 10993-1 biocompatibility testing and is applied in premium medical brands such as Mindray and United Imaging.

- Smart Logistics: In Mecanum wheel production, Feilong’s multi-component synchronous casting technology allows segmented control of both hardness (Shore A 75–95) and color within a single component.

Technological Heritage: Building a National Brand in Polyurethane Equipment

Since developing its first elastomer casting machine, Feilong has secured 56 national patents. Its core technologies, such as the “Polyurethane Casting Machine for Polymer Material Production”, have broken foreign monopolies in high-end polyurethane equipment manufacturing.

In collaboration with Academician Li Junxian’s research team from the Chinese Academy of Engineering, Feilong continues to advance frontiers in solvent-free polyurethane and nano-composite elastomers. Its 2023 innovation — supercritical CO₂-assisted foaming — reduces material density by 18% while maintaining mechanical strength, already applied in lightweight automotive components.

From giant mining rollers to micro precision casters for medical devices, Feilong’s medium-temperature polyurethane elastomer system is redefining industry benchmarks through innovation. With smart manufacturing on the rise, its integrated IIoT module now enables remote diagnostics and predictive maintenance, unlocking higher productivity and lower operating costs for polyurethane manufacturers.