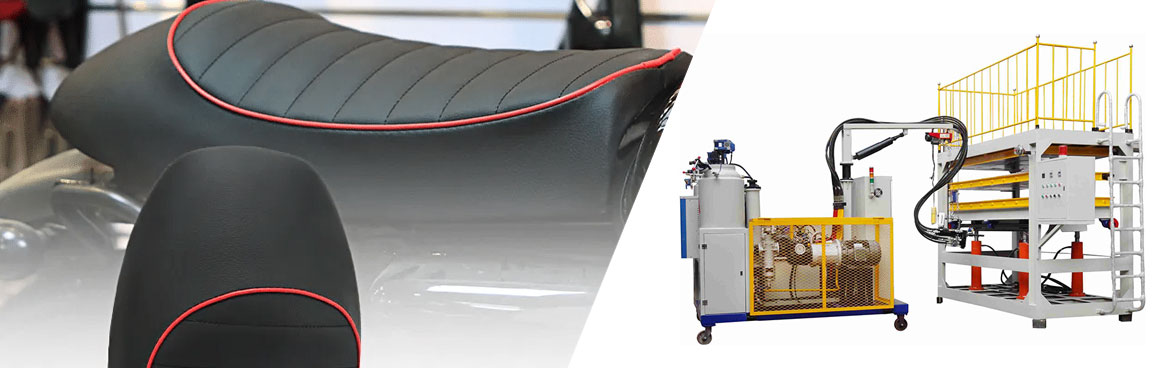

Technical Principle: Industrial Breakthrough with a Dual-Conveyor Synchronization System

Feilong Polyurethane Equipment’s foaming sheet laminating machine brings a revolutionary upgrade to motorcycle seat cushion production through dynamic temperature field control and continuous pressure compensation technology.

The machine adopts a dual-conveyor structure, with upper and lower conveyors each measuring 24 meters in length. The PID-controlled heating system maintains a precise temperature of 60°C ±2°C, ensuring that the polyurethane foaming reaction occurs under optimal thermodynamic conditions.

The production width is adjustable between 400 mm and 1200 mm, accommodating various seat types — from off-road single seats to cruiser double seats.

The production workflow is divided into three core stages:

- Preheating: The surface material is preheated to 55°C using an unwinder.

- Dynamic Mixing: The high-pressure foaming machine mixes isocyanate and polyol in a 1:1.2 ratio, with a mixing head speed of 4500 r/min for superior material homogeneity.

- Continuous Forming: During the 3–6 m/min conveyor process, the material undergoes uniform compression of 2000 N/m², achieving microstructural densification.

This continuous production model eliminates the efficiency bottlenecks of traditional batch processes, reducing unit energy consumption by 35%.

Core Parameters: Industrial-Grade Precision

The laminating machine demonstrates exceptional dynamic response and precision control:

- Speed Control: Servo motors provide stepless speed adjustment (3–6 m/min).

- Density Uniformity: A 24-meter heating zone ensures foaming density deviation within ±2 kg/m³ per square meter.

- Temperature Management: The Siemens PLC system monitors 16 temperature points, automatically activating hot-air circulation compensation when fluctuations exceed 3°C.

The modular heating design allows each 3 kW unit to operate independently.

The dual conveyors open up to 300 mm, supporting single-pass forming of cushions between 20–100 mm in thickness.

Quick-change side blocks reduce mold change time from 45 minutes to just 12 minutes, significantly improving line flexibility.

Certified with EU CE and ISO 9001, this machine is among the few domestic laminating systems qualified for high-end European markets.

Technical Comparison: Redefining Industry Standards

Compared to conventional processes, Feilong’s laminating machine sets new industry benchmarks in three dimensions:

- Process Integration: Converts multi-step batch operations into a single continuous flow — boosting efficiency by 300%.

- Product Consistency: Delivers ±3% density uniformity, versus ±8% in traditional molded processes.

- Design Flexibility: Enables R5 mm edge forming, breaking the R≥20 mm limitation of manual wrapping.

Future Trends: Smart Factories and Material Innovation

As motorcycle manufacturing embraces electrification, Feilong’s laminating technology is ready for the future.

Its integrated composite forming system can produce a built-in battery cavity within the seat base, maintaining ±0.5 mm precision — already compatible with BMW’s IIoT smart factory platform for remote monitoring and predictive maintenance.

On the materials front, the machine supports bio-based polyurethane processing. Even with 20% plant-derived polyol, seat performance remains stable.

Tests show these eco-friendly cushions withstand 50,000-cycle durability (EN 12520 standard) and comply with EU ECE R118 flammability regulations.

With global carbon neutrality goals accelerating, Feilong’s green and intelligent manufacturing capability will become a decisive advantage in the European and North American markets.