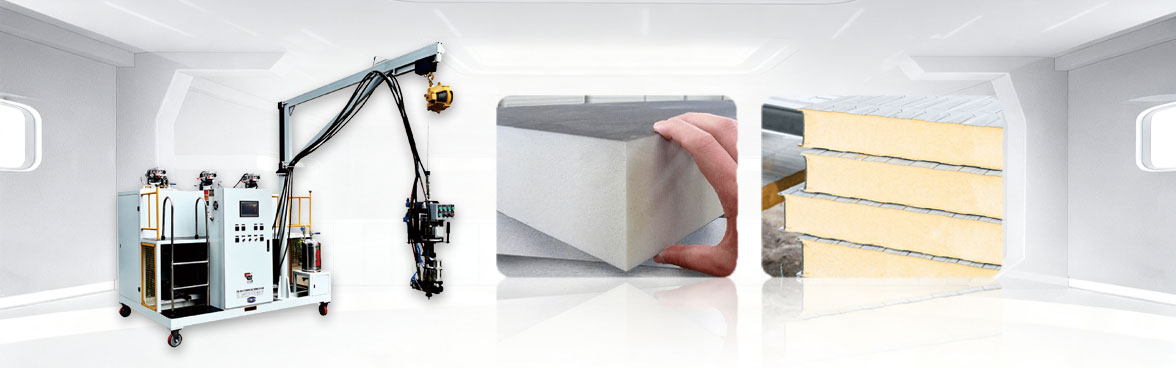

Fire-resistant polyurethane foam materials, as a class of high-performance composites, demonstrate immense potential across construction, transportation, and home appliance industries. Their unique closed-cell structure provides excellent thermal insulation, and with the addition of flame retardants, they can achieve the B1-level flame-retardant standard—making them an ideal choice for balancing safety and energy efficiency.

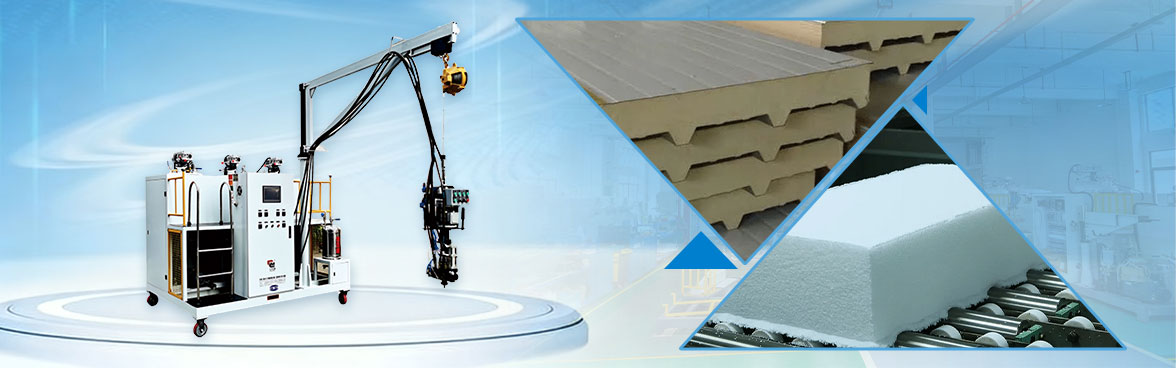

In the construction sector, fire-resistant polyurethane materials are gradually replacing traditional insulation materials. Data shows that buildings using B1-grade fire-resistant polyurethane insulation panels experience a fire spread rate more than 60% lower than those using traditional materials, while maintaining a thermal conductivity as low as 0.024 W/(m·K)—double the insulation efficiency of EPS. This “Safety + Energy Efficiency” advantage has driven a 15% annual growth rate in the material’s penetration across the green building market.

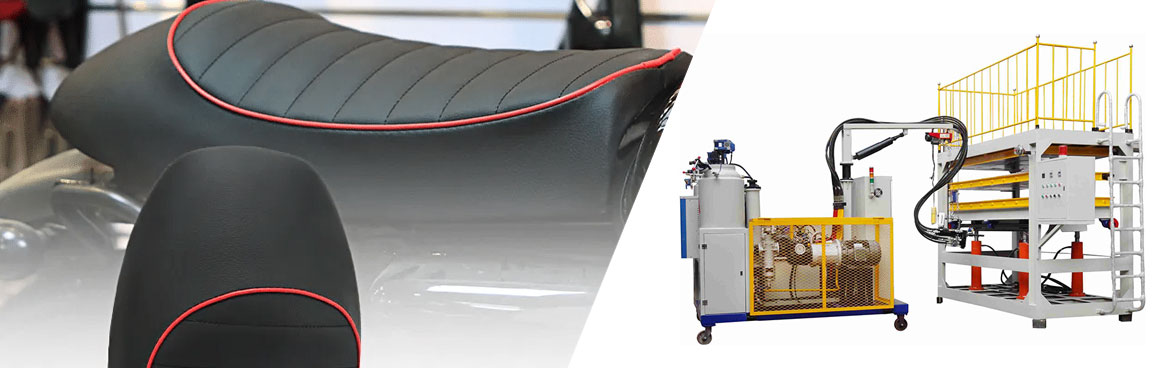

The transportation industry is also a major application field. As rail transit and new energy vehicles continue to expand rapidly, the requirements for fire safety in interior materials have become increasingly stringent.

In the home appliance industry, demand for fire-resistant polyurethane materials continues to grow. Refrigerators and freezers using these materials not only achieve a 20% improvement in insulation performance, but also significantly reduce fire risk. Industry statistics indicate that the fire incident rate of appliances using fire-resistant polyurethane is over 70% lower compared to conventional materials.

Equipment and Process Innovations

Feilong Polyurethane Equipment maintains a leading position in the production of fire-resistant polyurethane materials through the integration of its third-generation “Flash-Mix” mixing head technology and intelligent manufacturing system. This independently developed mixing technology achieves 99.2% uniformity, far exceeding industry averages, ensuring exceptional material consistency and stability.

Precise ratio control is another key to successful production. Feilong’s high-precision gear pump metering system keeps formulation deviations within ±1%, ensuring uniform distribution of flame retardants and base materials. This precision not only guarantees stable flame-retardant performance but also reduces raw material consumption by 10–15%, effectively cutting production costs.

The temperature control system further showcases Feilong’s technological superiority. With independent water-jacket heating and cooling systems, raw material temperatures are controlled within ±2 °C, maintaining stable chemical reactions. In fire-resistant polyurethane production, even a 5 °C fluctuation can cause uneven flame retardant dispersion, directly affecting product performance.

Intelligent automation is another highlight of Feilong’s production line. Its proprietary PLC control system monitors 128 process parameters in real time, including raw material temperature, pressure, and mixing ratio. The system features auto-correction capability, responding within 0.5 seconds when any parameter deviates from its preset range—minimizing human error and enhancing process reliability.

Material Performance and Safety Standards

Fire-resistant polyurethane materials produced with Feilong equipment strictly comply with national and industry standards, ensuring safety and reliability in all applications. While specific test results depend on individual product reports, materials from Feilong production lines consistently meet the GB 8624-2012 B1 flame-retardant standard, with oxygen index ≥ 28% and smoke density ≤ 75, satisfying demanding building and transportation requirements.

In terms of physical properties, materials exhibit outstanding mechanical stability. For example, rigid foams demonstrate compressive strength ≥ 0.3 MPa and dimensional stability ≤ 1.5% (70 °C, 48 h), ensuring long-term durability without deformation. Such results are made possible through Feilong’s advanced process control and precision engineering.

Thermal performance remains the core advantage. Materials produced by Feilong’s lines achieve thermal conductivity as low as 0.024 W/(m·K)—significantly lower than traditional insulators—and maintain heat distortion temperatures above 120 °C. This stability under high temperature helps preserve structural integrity during fire incidents, providing valuable time for evacuation and safety response.

Beyond performance, Feilong prioritizes environmental protection and operational safety. Its production lines feature sealed system designs to reduce VOC emissions, meeting the GB 18583-2008 standard for indoor environmental safety. Additionally, built-in safety mechanisms—such as emergency stop systems and overload protection—ensure secure and reliable production.

Conclusion

Through relentless innovation and a commitment to quality, Feilong Polyurethane Equipment has become a leader in the intelligent manufacturing of fire-resistant polyurethane materials. Its Flash-Mix mixing technology, precise metering systems, and intelligent control platforms provide strong technical support for consistent and efficient production. From building insulation to rail transit, and from home appliances to new energy vehicles, Feilong’s advanced equipment solutions are contributing to safer and more energy-efficient industries worldwide.