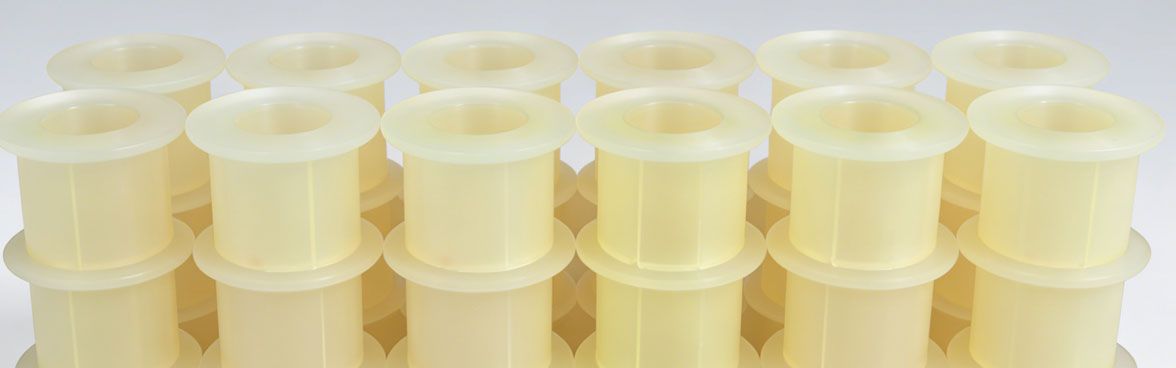

Against the backdrop of rapid growth in industrial automation and intelligent manufacturing, equipment safety, operational stability, and long-term durability have become core concerns for modern enterprises. As a critical buffering and protective component, industrial polyurethane bumpers are widely used in logistics conveyor systems, robotic end-effectors, automated warehousing, and heavy-duty equipment limit structures. These components effectively absorb impact energy, reduce mechanical wear, and enhance workplace safety.

Achieving consistent, high-performance polyurethane bumpers at scale, however, depends heavily on professional polyurethane processing equipment and integrated manufacturing solutions.

As a national high-tech enterprise with more than 30 years of experience in the polyurethane industry, Feilong Polyurethane Equipment has built strong technical expertise in specialized equipment for polymer and polyurethane elastomer processing. The company delivers comprehensive services spanning R&D support, equipment manufacturing, sales, installation, commissioning, and after-sales service. In parallel, Feilong also supplies high-quality polyurethane raw materials and finished products, offering customers a truly one-stop solution for polyurethane bumper and elastomer product manufacturing.

1. Professional Equipment Systems for Efficient Polyurethane Bumper Production

Polyurethane bumpers are typically produced using cast polyurethane elastomer (CPU) technology, which places stringent demands on raw material ratio accuracy, mixing uniformity, temperature control, and mold compatibility. To address these requirements, Feilong has developed a range of high-precision, application-specific systems:

- Polyurethane Elastomer Casting Machines Designed for small to medium batch production and applications requiring high elasticity, these systems feature precise metering, constant-temperature material conditioning, and optional vacuum degassing to ensure stable and consistent mechanical properties.

- Fully Automatic Mold Opening and Closing Systems Integrated with the casting machine, these systems enable automatic mold positioning, clamping, opening, and demolding. They significantly improve cycle efficiency and are especially suitable for standardized polyurethane bumper products requiring continuous production.

- Physical Foaming Systems (Optional) For applications requiring lightweight structures or specific energy-absorption characteristics, Feilong offers microcellular polyurethane foaming solutions that balance weight reduction with excellent impact absorption performance.

All Feilong equipment adopts a modular design philosophy, allowing flexible configuration based on customer capacity requirements. Remote monitoring, diagnostics, and maintenance support further ensure long-term production stability.

2. End-to-End Technical Services for Smooth Project Implementation

Feilong’s value proposition extends beyond equipment supply—it focuses on delivering complete manufacturing capability. The company provides full-process technical support, including project consultation, equipment selection, factory layout planning, on-site installation, operator training, and process optimization.

For specialized products such as polyurethane bumpers, Feilong’s engineering team works closely with customers to analyze operating conditions—including hardness requirements, dimensional specifications, and environmental exposure—and recommends optimized equipment configurations and process parameters. This approach shortens trial-production cycles and accelerates time to market.

All equipment is manufactured and tested under strict ISO quality management systems, with comprehensive performance verification and safety inspections to ensure compliance with relevant national standards and industry regulations.

Conclusion

Driven by Industry 4.0 and increasingly stringent safety requirements, the importance of polyurethane bumpers in industrial systems continues to grow. Anchored in over three decades of technical expertise, Feilong Polyurethane Equipment remains committed to providing highly reliable equipment and professional services that enable customers to manufacture polyurethane protection components with high performance, consistency, and cost efficiency.

Looking ahead, Feilong will continue to focus on application-specific innovation, promoting the polyurethane manufacturing industry toward greater intelligence, sustainability, and precision.