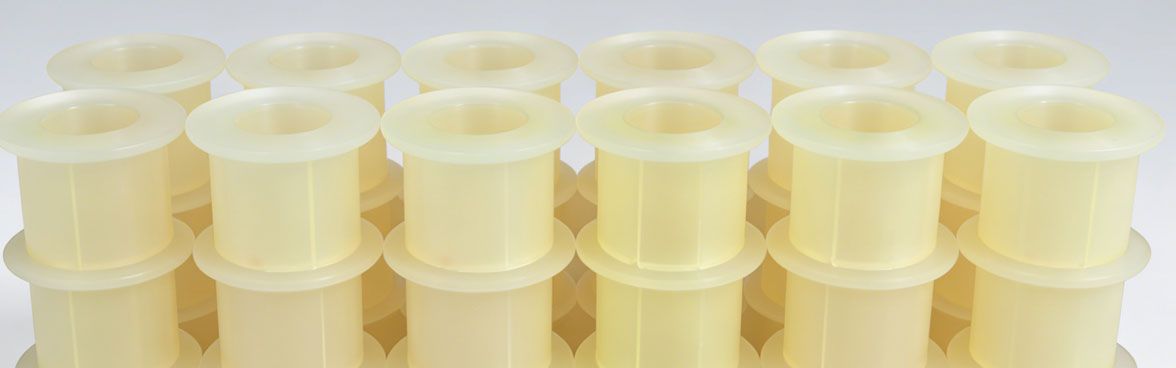

Across global industries such as industrial protection, transportation, consumer electronics, and outdoor equipment, demand continues to grow for materials that combine impact resistance, abrasion resistance, waterproofing, and vibration damping. Polyurethane (PU), with its outstanding mechanical properties and highly customizable formulations, has become an ideal material for manufacturing high-performance protective covers.

However, achieving stable mass production and consistent quality in PU protective covers depends not only on material selection, but also on professional, reliable, and efficient polyurethane processing equipment.

Integrated Polyurethane Solutions for PU Protective Cover Manufacturing

Feilong Polyurethane Equipment specializes in the system integration of dedicated polymer processing equipment, serving a wide range of industries including automotive, rail transit, construction, new energy, and consumer electronics. In the production of impact-resistant, wear-resistant, waterproof, and shock-absorbing PU protective covers, Feilong provides end-to-end solutions covering equipment, raw materials, and process support.

PU protective covers are typically manufactured using casting or foaming processes, which impose stringent requirements on metering accuracy, mixing uniformity, temperature stability, and automation levels. To meet these demands, Feilong offers the following key equipment solutions:

Core Equipment for PU Protective Cover Production

Polyurethane Elastomer Casting Machines

Designed for high-hardness and high-elasticity solid PU protective covers, these machines feature high-precision dual-component metering systems, optional static or dynamic mixing heads, and PLC-based intelligent control. This ensures excellent product consistency and high yield rates.

High- and Low-Pressure Polyurethane Foaming Machines

These systems support the production of foamed protective covers with varying densities and internal structures. Low-pressure machines are ideal for small-batch and flexible manufacturing, while high-pressure machines are optimized for large-scale, high-efficiency production lines and are particularly suitable for physical foaming processes.

Fully Automatic Mold Opening and Closing Systems

Integrated with automatic mold positioning, clamping, and demolding functions, these systems significantly improve production cycle times, reduce manual intervention, and ensure dimensional accuracy for complex protective cover designs.

Physical Foaming Equipment

In response to global environmental and sustainability trends, Feilong provides equipment compatible with water- and CO₂-based physical foaming systems, enabling customers to achieve greener, low-carbon PU production.

Customized Turnkey Production Lines

Based on specific product structures, capacity requirements, and automation targets, Feilong can also deliver customized turnkey production lines. The system integration expertise demonstrated in solutions such as fully automated automotive seat production lines can be effectively adapted to high-end intelligent manufacturing lines for PU protective covers.

Conclusion

Behind every high-performance PU protective cover lies a deep understanding of material science and precision manufacturing. With more than 30 years of technical expertise, a rigorous engineering philosophy, and an open approach to collaboration, Feilong Polyurethane Equipment is committed to being a trusted global partner for polyurethane machinery and integrated solutions.