With the rapid global growth of the plastic packaging, flexible packaging, and composite materials industries, bag-making machines have become critical equipment in modern production lines. As one of their most essential functional components, rubber rollers directly determine sealing quality, operational stability, and overall production efficiency.

The performance of these rollers—especially their wear resistance, dimensional stability, and service life—depends heavily on the polyurethane materials, processing technology, and dedicated equipment used in manufacturing.

As a professional manufacturer with more than 30 years of experience in the polyurethane industry, Feilong Polyurethane Equipment leverages its deep expertise in polyurethane elastomer formulation, precision casting machinery, and integrated system solutions to deliver high-precision, long-life bag-making machine roller solutions for customers worldwide.

1. Three Decades of Focus on Polyurethane: A Solid Technological Foundation

Since its establishment, Feilong has remained dedicated to the R&D and manufacturing of specialized equipment for polymer and polyurethane applications. Its core product portfolio includes:

- Polyurethane elastomer casting machines

- High- and low-pressure polyurethane foaming machines

- Fully automatic automotive seat production lines

- Automatic mold opening and closing systems

- Specialized physical foaming equipment

Beyond equipment manufacturing, Feilong also supplies high-quality polyurethane raw materials and customized finished products, forming a comprehensive “equipment + materials + process” integrated service model.

This vertically integrated capability allows Feilong to control key parameters from the source—such as mechanical performance, dimensional accuracy, and long-term durability—ensuring consistent and reliable rubber roller quality.

2. Why Polyurethane for Bag-Making Machine Rollers?

How Feilong Achieves High Precision and Long Service Life

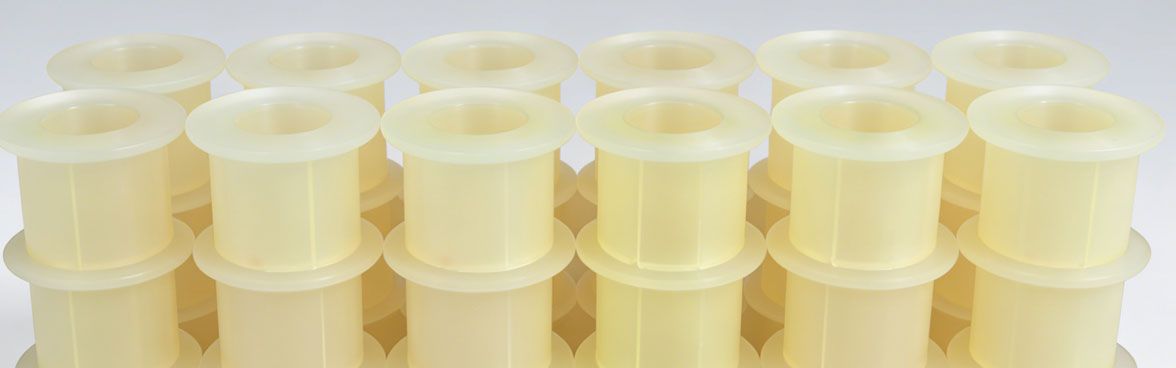

Bag-making machine rollers must exhibit excellent wear resistance, tear strength, elastic recovery, and surface smoothness, while maintaining dimensional stability under high-speed operation. Traditional rubber or metal rollers struggle to meet all these requirements simultaneously.

Polyurethane elastomers, with adjustable hardness (Shore A 60–95), high load-bearing capacity, and low compression set, have become the preferred solution for modern bag-making equipment.

Feilong ensures superior roller performance through the following key technologies:

1) Precision Formulation Engineering

Based on specific operating conditions—such as high-temperature sealing, high-speed rotation, or solvent exposure—Feilong customizes prepolymer and chain extender ratios to optimize mechanical strength, resilience, and aging resistance.

2) High-Vacuum Casting Process

Using self-developed polyurethane elastomer casting machines, mixing and pouring are completed under high-vacuum conditions, eliminating air bubbles and impurities and ensuring a dense, uniform roller structure.

3) Intelligent Temperature-Controlled Curing

Accurate control of curing temperature and time curves ensures complete crosslinking reactions, significantly enhancing internal structural stability and service life.

4) CNC Precision Machining and Dynamic Balancing

After molding, rollers undergo high-precision CNC turning and grinding. Radial runout is controlled within ±0.02 mm, followed by dynamic balancing to meet the requirements of high-speed bag-making machines.

5) Strict Quality Inspection

Each roller is tested for hardness, concentricity, surface roughness, and load performance, ensuring reliable performance and immediate usability upon delivery.

Conclusion

As global manufacturing moves toward higher efficiency, sustainability, and intelligent production, Feilong Polyurethane Equipment continues to drive innovation through technology and customer-centric solutions. By delivering cost-effective, highly reliable polyurethane equipment and roller products, Feilong empowers partners worldwide to enhance productivity and long-term competitiveness in the packaging industry.