As global energy-efficiency targets and green building standards continue to rise, polyurethane (PU) insulated pipelines have become a critical solution for district heating, district cooling, oil and gas transportation, and industrial fluid systems. Thanks to their outstanding thermal insulation performance, structural strength, and ease of installation, PU insulated pipes play a decisive role in reducing energy losses and improving system reliability throughout the pipeline lifecycle.

1. Three Decades of Technical Expertise Building a Specialized PU Equipment System

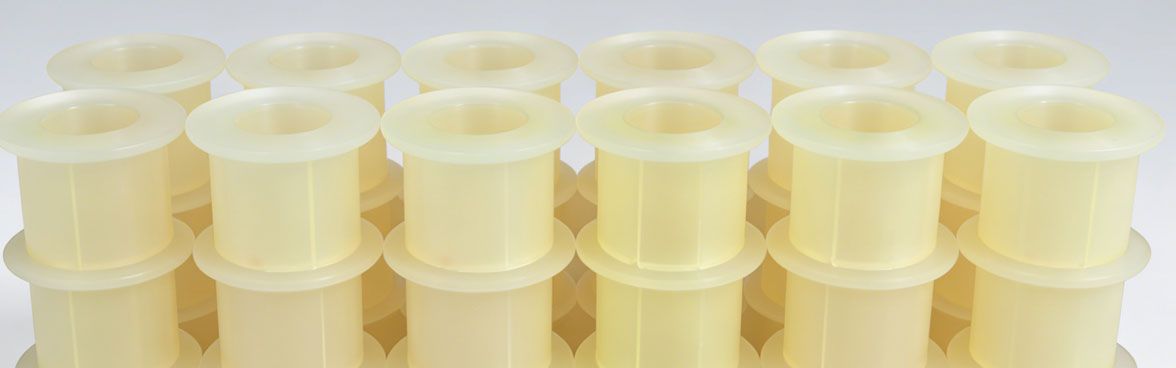

With more than 30 years of accumulated experience in polyurethane processing technology, Feilong Polyurethane Equipment has developed a mature and application-oriented equipment portfolio dedicated to insulated pipe manufacturing. Its solutions are designed to accommodate a wide range of pipe diameters (DN25–DN1200), operating conditions (high-temperature hot water, low-temperature chilled water, steam-tracing systems), and construction methods, including factory prefabrication and on-site foaming.

By combining proven mechanical design with advanced process control, Feilong ensures stable foaming performance and consistent insulation quality across diverse global markets and standards.

2. Flexible Configuration for Diverse Pipe Insulation Applications

The core performance of a polyurethane insulated pipe lies in achieving a uniform, dense, and void-free foam layer. This outcome is highly dependent on the metering accuracy, mixing efficiency, and overall process stability of the foaming equipment. Feilong’s high- and low-pressure PU foaming machine series delivers clear technical advantages:

- High-Precision Ratio Control A/B component metering accuracy of ≤ ±1%, ensuring complete chemical reactions and stable foam properties.

- Modular Equipment Design Scalable configurations tailored to customer production needs, from small-batch pilot production to high-volume continuous manufacturing lines.

- Intelligent Control System PLC + HMI architecture with parameter storage and recall functions, enabling fast changeovers between different pipe specifications.

- Compatibility with Multiple Foaming Systems Supports conventional HCFC and cyclopentane systems, as well as next-generation environmentally friendly HFO and water-blown technologies, helping customers comply with international environmental regulations such as the EU F-Gas Regulation and the EPA SNAP program.

Conclusion

Whether for newly constructed large-scale district heating networks or energy-efficiency retrofits of aging pipeline infrastructure, selecting a reliable, flexible, and environmentally compliant PU insulated pipe production system is essential. Anchored by 30 years of industry expertise and driven by customer-oriented engineering, Feilong Polyurethane Equipment is committed to serving as a trusted global partner for high-performance polyurethane insulation solutions.