In modern industrial automation, precision assembly, and heavy machinery operations, vibration damping, shock absorption, and sealing performance are directly linked to equipment lifespan, operational stability, and maintenance costs. As a critical functional component, industrial polyurethane elastic rings—commonly known as PU circular buffer pads—have become the preferred solution across high-end manufacturing sectors due to their outstanding physical and chemical properties. Behind this high-value product chain, advanced production equipment plays a decisive role.

With more than two decades of specialization in polyurethane machinery, Feilong Polyurethane Equipment provides systematic, reliable solutions that enable customers to manufacture high-quality PU buffer pads efficiently and consistently.

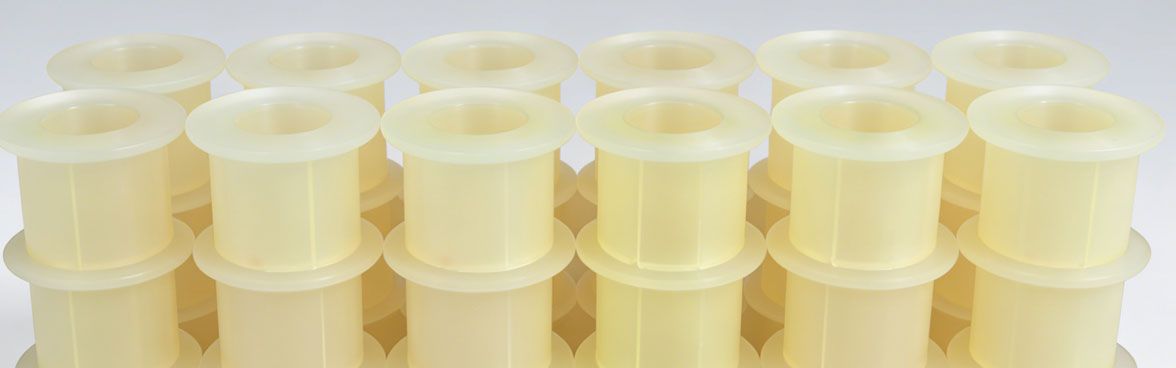

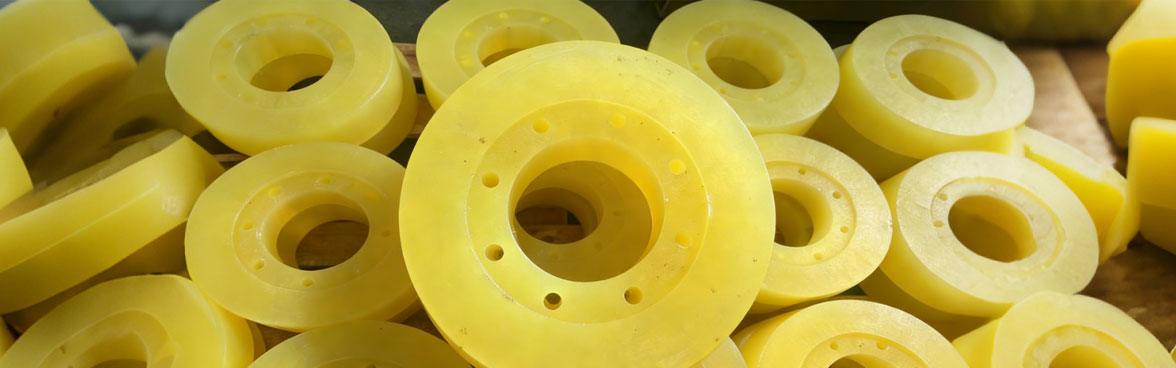

1. Polyurethane Elastic Rings: The “Flexible Joints” of Industrial Systems

Polyurethane (PU) materials are widely recognized for their high elasticity, excellent wear resistance, tear strength, and superior resistance to oil and aging. Compared with traditional rubber or metal spring components, PU circular buffer pads offer several distinct advantages:

- High Load Capacity with Low Compression Set Maintains elastic recovery under continuous compression, ideal for high-frequency vibration environments.

- Wide Operating Temperature Range Stable performance from –40°C to +100°C, suitable for most industrial applications.

- Broad Customizable Hardness Range Typical Shore hardness from 60A to 95A, balancing cushioning performance and structural support.

- Excellent Wear and Impact Resistance Significantly extends component service life and reduces downtime and maintenance frequency.

Typical applications include buffering for automated assembly fixtures, sealing elements in hydraulic systems for construction machinery, vibration-damping components in rail transportation, and non-contaminating contact parts in food and pharmaceutical equipment.

As intelligent manufacturing and green production continue to evolve, higher standards are being placed on the consistency, cleanliness, and functional integration of PU buffer pads—driving the need for upgraded manufacturing processes and equipment.

2. Feilong: Over 20 Years of Expertise in Polyurethane Molding Equipment

Feilong Polyurethane Equipment has long been dedicated to the R&D, manufacturing, and technical service of polyurethane molding machinery. Leveraging the strong industrial ecosystem of Zhejiang, one of China’s major manufacturing hubs, Feilong has developed a comprehensive equipment portfolio covering the entire production process, including raw material metering, mixing, injection, molding, and post-processing.

Through deep understanding of polyurethane reaction characteristics and long-term customer feedback, Feilong has established a core equipment philosophy centered on high precision, high stability, and high adaptability. Its equipment is widely used in automotive, electronics, home appliances, construction, and industrial components, serving hundreds of PU product manufacturers worldwide and earning a strong reputation within the industry.

3. Integrated Technical Solutions for PU Buffer Pad Production

To address the key challenges in industrial PU circular buffer pad manufacturing—such as small-batch multi-specification production, high dimensional accuracy, and low bubble rate—Feilong offers a series of specialized equipment and technical support solutions:

- High-Precision Low-Pressure Casting Machines Equipped with servo-driven metering and closed-loop control systems, ensuring A/B component ratio accuracy within ±1%, effectively preventing hardness inconsistency or incomplete curing.

- Modular Mold Temperature Control Systems Support rapid mold changes and precise temperature regulation (±2°C), ensuring excellent surface finish and dense internal structure of the pads.

- Automated Demolding and Post-Processing Units Integrated robotic demolding, trimming, and inspection stations enhance production automation and reduce quality fluctuations caused by manual intervention.

- Process Parameter Database and Remote Diagnostic Services Based on extensive project experience, Feilong provides optimized matching recommendations among formulations, equipment, and processes, while enabling equipment condition monitoring and fault warnings via IoT platforms.

In addition, Feilong emphasizes a dual-drive strategy of “equipment + process”. Its technical team supports customers throughout the entire lifecycle—from product design validation and mold development to mass production ramp-up—significantly shortening time to market.

4. Creating Sustainable Value for Customers

Feilong’s core value lies not only in supplying equipment, but in delivering professional solutions that help customers achieve three major improvements:

- Higher Production Efficiency Automation and intelligent configurations reduce labor dependence, increasing single-line capacity by over 30%.

- Stable Product Consistency Precision metering and temperature control ensure consistent performance across batches, meeting ISO/TS and other quality system requirements.

- Stronger Market Competitiveness Flexible equipment design enables rapid response to small-batch and customized orders, helping customers establish differentiation in niche markets.

Against the backdrop of carbon-reduction goals and industrial upgrading, efficient, energy-saving, and low-waste polyurethane manufacturing has become an industry consensus. Feilong continues to optimize equipment energy efficiency and material utilization, supporting customers in their transition toward greener production.

Conclusion

Though small in size, industrial polyurethane elastic rings play a crucial role in ensuring the reliable operation of modern equipment. With more than 20 years of technical expertise and a strong customer-oriented approach, Feilong Polyurethane Equipment has become a trusted partner for PU product manufacturers. Looking ahead, Feilong will continue to focus on innovation in polymer molding equipment, driving the polyurethane industry toward higher precision, greater efficiency, and higher added value.