In today’s rapidly evolving field of polymer materials, polyurethane (PU) has become one of the most versatile and widely adopted materials due to its outstanding mechanical properties, wear resistance, and high design flexibility. It is extensively used across industries such as automotive, rail transit, electronics and electrical appliances, building insulation, and high-end manufacturing.

As a critical pillar of the polyurethane value chain, specialized equipment for PU processing plays a decisive role in formulation validation efficiency, product consistency, and the successful transition from R&D to industrial-scale production. Equipment performance directly impacts reaction stability, material uniformity, and the reproducibility of final products.

Comprehensive Equipment Coverage from Lab-Scale to Mass Production

Feilong Polyurethane Equipment has long been dedicated to the research, development, manufacturing, sales, and technical service of specialized equipment for polymer composite materials. Over years of industry accumulation, Feilong has established a full-spectrum equipment system covering laboratory trials, pilot-scale validation, and industrial mass production—providing customers with a seamless, end-to-end solution.

Core Product Portfolio

Feilong’s core polyurethane equipment lineup includes:

Polyurethane Elastomer Casting Machines

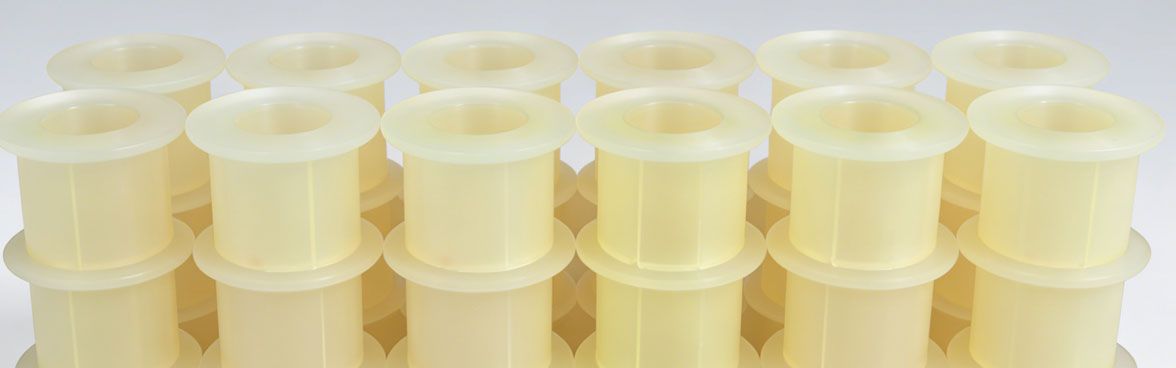

Designed for cast polyurethane elastomers using common chain extenders such as MOCA (4,4′-methylene bis(2-chloroaniline)) and BDO (1,4-butanediol), these machines feature high-precision metering, stable temperature control, vacuum degassing, and programmable casting processes. They ensure excellent material consistency and repeatability for demanding elastomer applications.

High- and Low-Pressure Polyurethane Foaming Machines

Capable of handling flexible foam, rigid foam, and semi-rigid foam processes, these systems are widely applied in thermal insulation, cushioning, structural components, and other functional PU products.

Fully Automated Automotive Seat Production Lines

Integrating raw material conveying, mixing, pouring, curing, and demolding systems, these production lines enable high-efficiency and stable manufacturing of automotive seat foam components while meeting stringent quality requirements.

Automatic Mold Opening and Closing Systems

Used in conjunction with casting and foaming machines, these systems significantly improve mold changeover efficiency, reduce labor intensity, and enhance molding consistency.

Physical Foaming Equipment

Compatible with physical blowing agents such as CO₂ and water-based systems, this equipment supports manufacturers in achieving greener, low-carbon production processes in line with sustainability goals.

Dedicated Polyurethane Elastomer Formula Testing Machine for R&D

Of particular note is Feilong’s Polyurethane Elastomer Formula Testing Machine, developed specifically to address the urgent need for rapid formulation verification in research institutes and corporate R&D centers.

Engineered for laboratory environments, this machine supports small-batch casting operations (typically 50 g–2 kg) and enables precise control over A/B component ratios, reaction temperatures, and mixing speeds. It is especially suitable for cast elastomer formulations using MOCA or BDO chain extenders, making it an ideal tool for formulation screening and process parameter optimization.

Thanks to its modular design, the system is easy to clean and maintain, significantly reducing development cycles and trial-and-error costs while accelerating the transition from laboratory innovation to scalable production.

Conclusion

As polyurethane materials continue to evolve toward higher performance, enhanced functionality, and greener manufacturing, Feilong Polyurethane Equipment stands out as a vital bridge between laboratory innovation and industrial realization. Backed by deep industry expertise and continuous technological innovation, Feilong delivers reliable, customized equipment and technical support for a wide range of users.

Whether supporting universities and research institutes in advanced elastomer exploration or assisting manufacturing enterprises in production line upgrades, Feilong Polyurethane Equipment provides practical, trustworthy, and future-ready solutions across the entire polyurethane development and manufacturing lifecycle.