In the spring damper manufacturing industry, competition has long moved beyond the question of whether you can produce—it now centers on how well, how consistently, and how cost-effectively you do so.

Yet many manufacturers remain trapped in an invisible efficiency gap: on the surface, production capacity appears sufficient, but in reality, profits are quietly eroded by inefficient processes. High raw material waste rates, unstable performance between batches, frequent equipment downtime, and delayed deliveries are often dismissed as “industry norms.” In truth, these are systemic problems with systematic solutions.

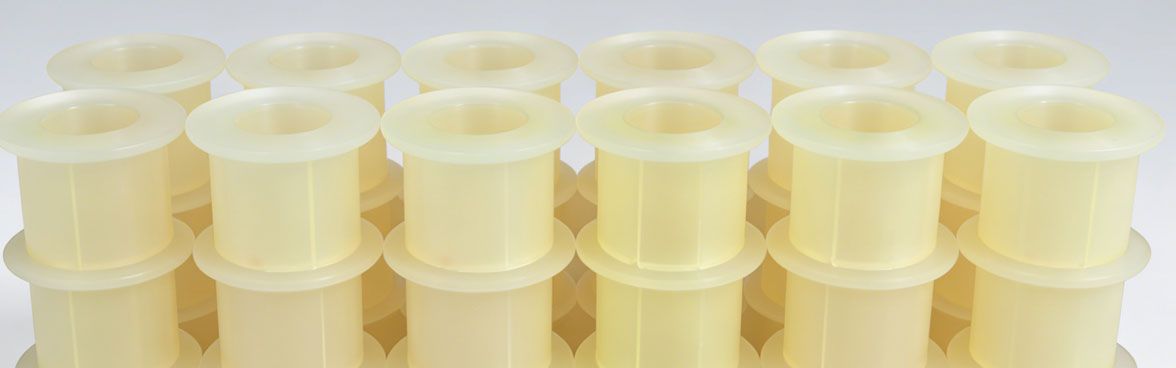

More often than not, the root cause lies in a piece of equipment used every day but rarely re-examined—the polyurethane foaming system.

The Real Cost Is Not Where Most Manufacturers Look

When cost optimization is discussed, many spring damper manufacturers focus on negotiating raw material prices or compressing labor costs. What is frequently overlooked is the hidden loss embedded in the process itself:

- Inconsistent foam density → Unstable damping performance → Product returns or downgraded applications → Long-term damage to brand credibility

- Deviation in mixing ratios → Abnormal curing behavior → Sharp increases in scrap rates → Rising unit costs with no visible warning

- Complex cleaning procedures and long mold-change times → Frequent production interruptions → Capacity utilization falling below 70% → Increasing pressure on delivery schedules

These challenges are not caused by operator error. They stem from equipment that lacks adaptability to complex and variable production conditions.

Rebuilding the Damper Production Logic with Precision Control

Feilong Polyurethane Equipment does not design generic machines. We engineer application-specific solutions for spring damper manufacturing, addressing the real operational pain points behind hidden costs.

Dynamic Ratio Self-Adjustment Technology

Different damping requirements—such as automotive suspension systems versus industrial vibration isolators—demand different material behaviors. Feilong systems automatically fine-tune the A/B material ratio in real time, ensuring foam density deviation remains within ±1.5% across batches. Production no longer relies on manual trial-and-error adjustments.

Zero-Residue Flow Channels and Rapid Mold-Change Systems

Optimized flow path design minimizes material retention, while fast mold-change mechanisms reduce cleaning time by up to 60% and improve changeover efficiency by three times. Small-batch, multi-specification orders are no longer a production burden—they become a competitive advantage.

Closed-Loop Temperature Control and Pressure Compensation

Environmental temperature fluctuations and raw material batch differences are inevitable. Feilong equipment automatically compensates process parameters, maintaining consistent mechanical performance and damping characteristics under varying conditions.

Conclusion: True Cost Reduction Starts with Process Control

The next phase of industry consolidation will favor manufacturers who are willing to confront hidden inefficiencies head-on.

While competitors celebrate marginal improvements in yield, precision foaming technology allows you to build a structural cost advantage—one rooted in stability, repeatability, and intelligent control. In spring damper manufacturing, efficiency is no longer about running faster; it is about producing smarter.