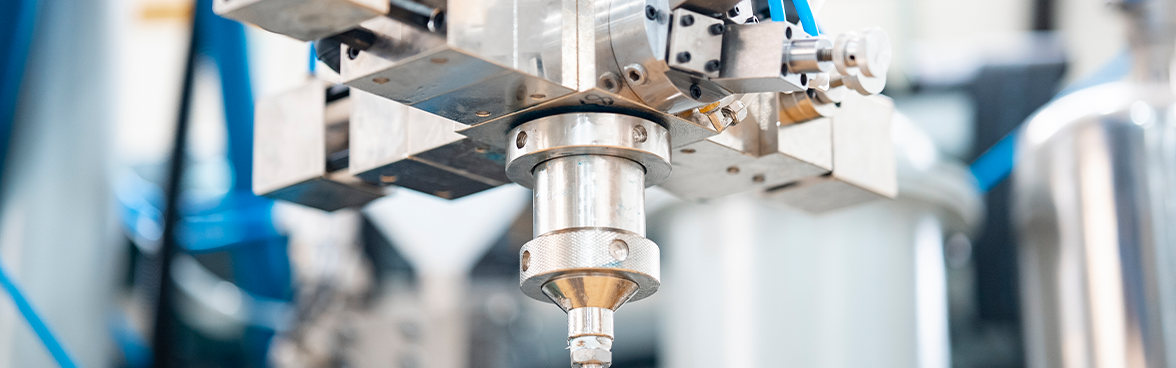

In the field of polyurethane product manufacturing - whether it's the flexible rebound of car seat cushions, the tight insulation of building insulation boards, or the seamless sealing strips for cold chain - none of these would be possible without a "heart device": the polyurethane foaming machine. Its performance directly affects the uniformity of the products, bubble control, and final quality. Among many domestic equipment brands, Feilong polyurethane machinery equipment, with twenty years of technical expertise, is redefining the industry's production standards through its star models such as PU20F-Y/R series and CPU20F(S)-G series.

1. Why is the foaming machine the "key" to polyurethane production?

Polyurethane foaming is not a simple mixing reaction. Its core lies in precisely proportioning and uniformly mixing the two-component raw materials of polyol and isocyanate at high temperature and under high pressure, and then spraying and forming. During the process:

• Temperature fluctuations exceeding ±1℃ - The reaction rate becomes unbalanced, resulting in uneven foaming or collapse.

• Measurement error > 1% - The hardness of the product fails to meet the standard, and the scrap rate soars.

• Residual bubbles - The product's insulation performance and mechanical properties deteriorate comprehensively.

Traditional equipment often experiences frequent problems due to insufficient precision and uneven mixing. However, the Feilong polyurethane machinery equipment has overcome these issues through three core technologies, precisely targeting the industry's pain points.

II. Leading Models of Feilong Polyurethane Machinery and Equipment: Injecting "Strength" into High-End Manufacturing

1. PU20F-Y/R Series Foaming Machine: All-Rounder

• Three-dimensional movable pouring head: Supports full-directional adjustment (front, rear, left, right, up and down), suitable for filling requirements of complex molds such as car seat cushions and cold storage panels.

• ±0.5% measurement accuracy: Equipped with a low-speed high-precision metering pump, even if the material temperature and viscosity fluctuate, it ensures a constant mixing ratio, reducing scrap rate by over 40%.

• Automatic cleaning system: Completes pipeline cleaning in 5 minutes when switching raw materials, saving 30% of downtime.

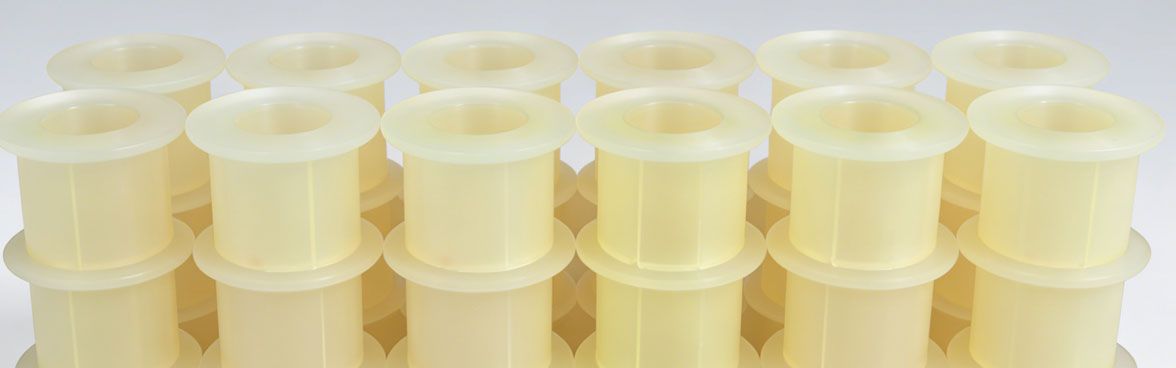

2. CPU20F(S)-G Elastomer Pouring Machine: Benchmark for No-Bubble Process

• Micro-bubble elimination technology: Unique guide needle and vibration elastic plate design, piercing and expelling bubbles in the raw material flow path, achieving "macroscopic no bubbles" in the products.

• Color paste direct mixing system: Directly injects color paste into the mixing head, avoiding contamination of the main material tank and reducing cleaning consumables by 90%.

• PLC touch control integration: Temperature control accuracy ±2℃, process parameters can be stored and called, and product types can be switched with one click.

Case Verification: After using the G series equipment, a car sealing strip factory reduced the return rate caused by bubbles from 8% to 0.2%, and the color paste replacement efficiency increased by 4 times.

III. Beyond Equipment: How Feilong Polyurethane Machinery Constructs a Technical Fortress?

The competitiveness of Feilong Polyurethane Machinery lies not only in the performance of individual machines, but also in its systematic innovation capabilities:

• Deep integration of industry-university-research: It has the earliest domestic expert team specializing in polyurethane equipment research and development, continuously iterating the structure of mixing heads and control algorithms.

• Modular design concept: For example, the pouring head can be quickly replaced, and the same machine can be adapted for various production scenarios such as rigid foam (insulation board), soft foam (bedding), and elastomers (sealing strips).

• Green and energy-saving genes: It consumes 15% less energy than traditional models, aligning with the national dual-carbon policy orientation.

IV. New Industry Trends: The Future Battlefield of Feilong Equipment

With the upgrading of downstream applications, the demand for equipment is expanding in two dimensions:

1. Ultra-high flow direction: For example, insulation for a 1.6-meter-diameter pipeline requires equipment of the PU600 grade (600 L/min). Feilong polyurethane machinery equipment has already prepared large-flow models to meet this demand.

2. Intelligent and flexible production: An XY-axis conformal platform integrated with visual positioning (such as the casting machine for filter seal pads), enables the transformation to a "dark factory".

Conclusion: Choosing equipment is choosing the productivity gene

In the process of the polyurethane industry moving from a "production giant" to a "production power", domestic equipment manufacturers represented by Feilong polyurethane machinery equipment have proven that high precision, zero bubbles, and intelligence are no longer exclusive to imported brands. When a foaming machine can keep the temperature fluctuation within ±2℃, make the color paste switching as simple as changing a pen芯, and continuously reduce the energy consumption per cubic meter of foam - it not only brings enterprises product qualification rates but also defines their ability to dominate the high-end market.

Action suggestion: If you are facing bubble problems, frequent cleaning, or order flexibility pressure, you might want to deeply evaluate the Feilong polyurethane machinery equipment series PU20F-Y/R or CPU20F(S)-G - which have already verified revolutionary productivity in industries such as insulation pipes, automotive parts, and furniture. In the era of precise manufacturing, equipment selection will determine your position on the track for the next five years.